Rugged and precise bulk bag filling machines

Whether you need to store or process large quantities of bulk material, transfer them to smaller packages, or contain the final product before shipment, we can provide a bulk bag filler that meets your needs.

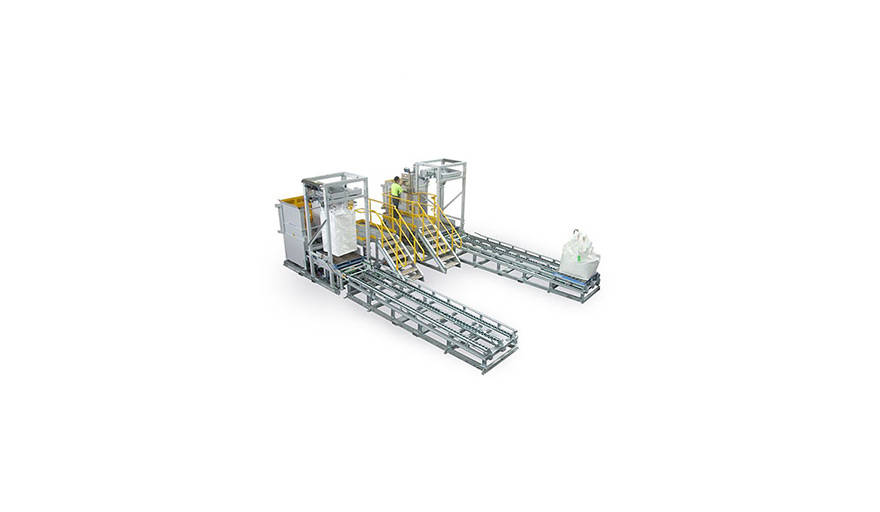

Our bulk bag filling machines can handle up to 4,400 lb of powders, granules, flakes, or pellets. Compared to manual filling, they significantly save time and labor. Our machine can be customized with various automation levels and can be enhanced with additional bulk bag handling equipment.

With the technical expertise gained through our legacy brands, Kockums Bulk Systems, and B.A.G. Equip., we support businesses in the food, feed, chemicals, minerals, seeds, and organics industries to streamline their operations.

How bulk bag fillers work?

An empty pallet is placed on the bagger's platform via forklift or conveyor. The operator places the FIBC bag on the filling head, and the big bag filler dispenses the material, often using a weight controller for accurate filling.

Once the filling is complete, the operator ties up the bag before further processing or shipment.

Our bulk bag fillers

Our bulk bag filling machines are manufactured locally, and offerings vary by region.

Highly accurate and precise weighing

Our bulk bag fillers boast exceptional precision, up to +/- 0.2% accuracy in packed weight. This is achieved by controlling the product flow rate combined with advanced weighing technologies.

Varying levels of automation

Depending on your needs, operators may manually handle tasks such as moving pallets and placing bags, or you can opt for additional automation features like a pallet dispenser with infeed and outfeed conveyors.

Clean operations

Our bulk bag fillers are designed to minimize dust emission and prevent cross-contamination with stainless-steel contact surfaces and collection ports that contribute to a clean environment.

Heavy-duty design

The hydraulic-free, simple, and rugged design of our bulk baggers ensures easy and cost-effective operations.

These machines feature a heavy-duty lift and weighing frame, making them easy to use and maintain.

Intuitive and easy to operate

The operator platform's proximity to the filling station allows for easy access to the bag hooks.

These bag filling machines are controlled via a PLC with a user-friendly HMI.

Held to the highest safety standards

Our bulk bag filling equipment can be equipped with the latest in safety features:

- Dust collection ports

- Emergency-stops

- Light curtains

- Safety fences

- Performance Level D compliance

Additional available features

We care about making your bulk bag filling line as functional as possible, offering a selection of integrations to meet your specific needs.

- Automatic pallet dispenser

- Slip sheet dispenser

- Bag inflation and controlled dedusting to ease the filling process

- Densification systems to improve stability and handling

- Bulk/dribble feeding devices

- Filling spout/hooks height adjustment

- Infeed and outfeed conveyors

- Checkweigher

Get a quote

Tell us more about your project and we will send you recommendations and a free quote.

Lifecycle management

Personalized customer service to maximize your equipment performance and lifespan

Lifecycle management

Personalized customer service to maximize your equipment performance and lifespan

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Operator training

Practical operator training that ensures a smooth transition to automation

Operator training

Practical operator training that ensures a smooth transition to automation

Need help choosing the right bulk bag filler?

Request a quote

Tell us about your project, and we will reply with solution recommendations