Accurate and reliable valve bag packers

Enhance your packaging efficiency, product quality, and employees’ safety with our versatile valve bag fillers.

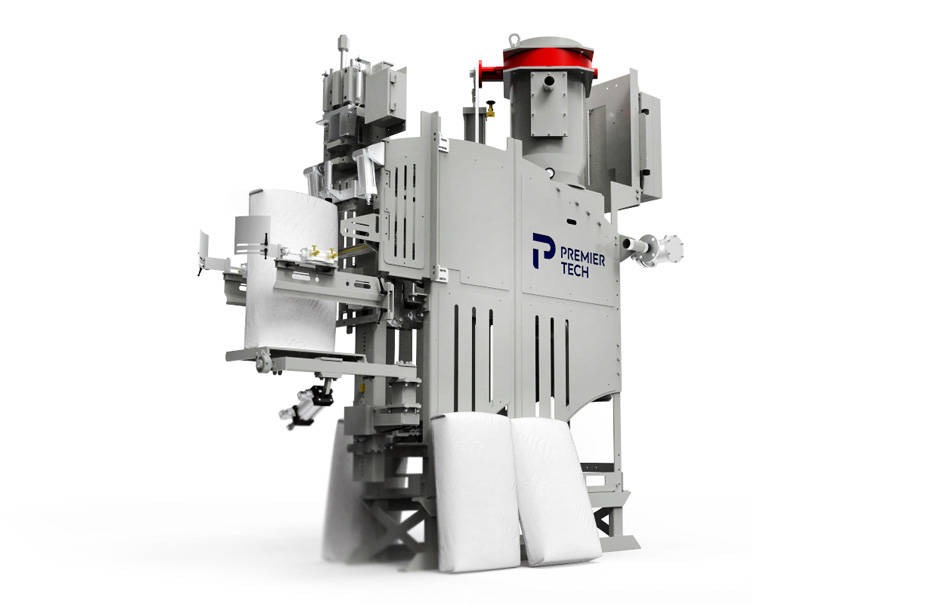

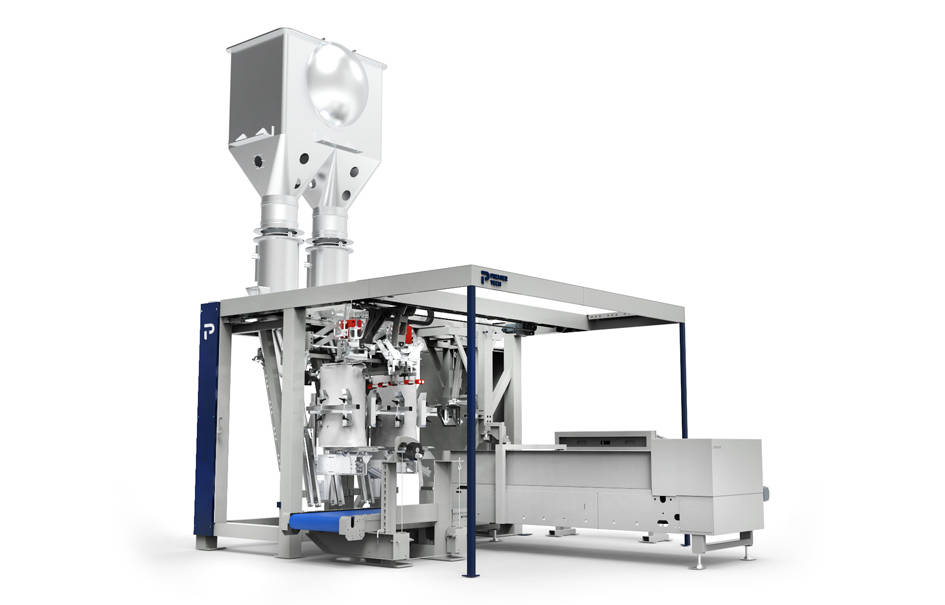

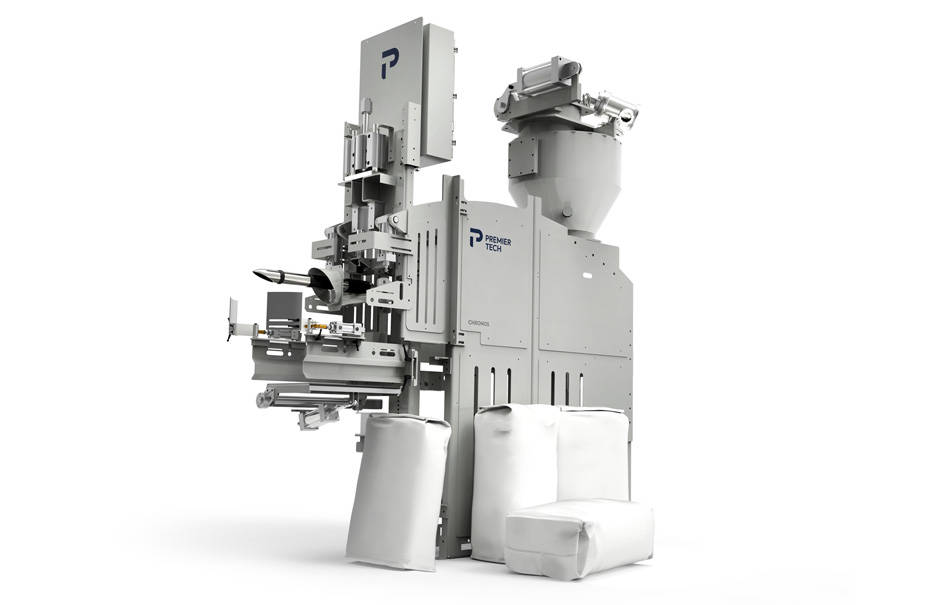

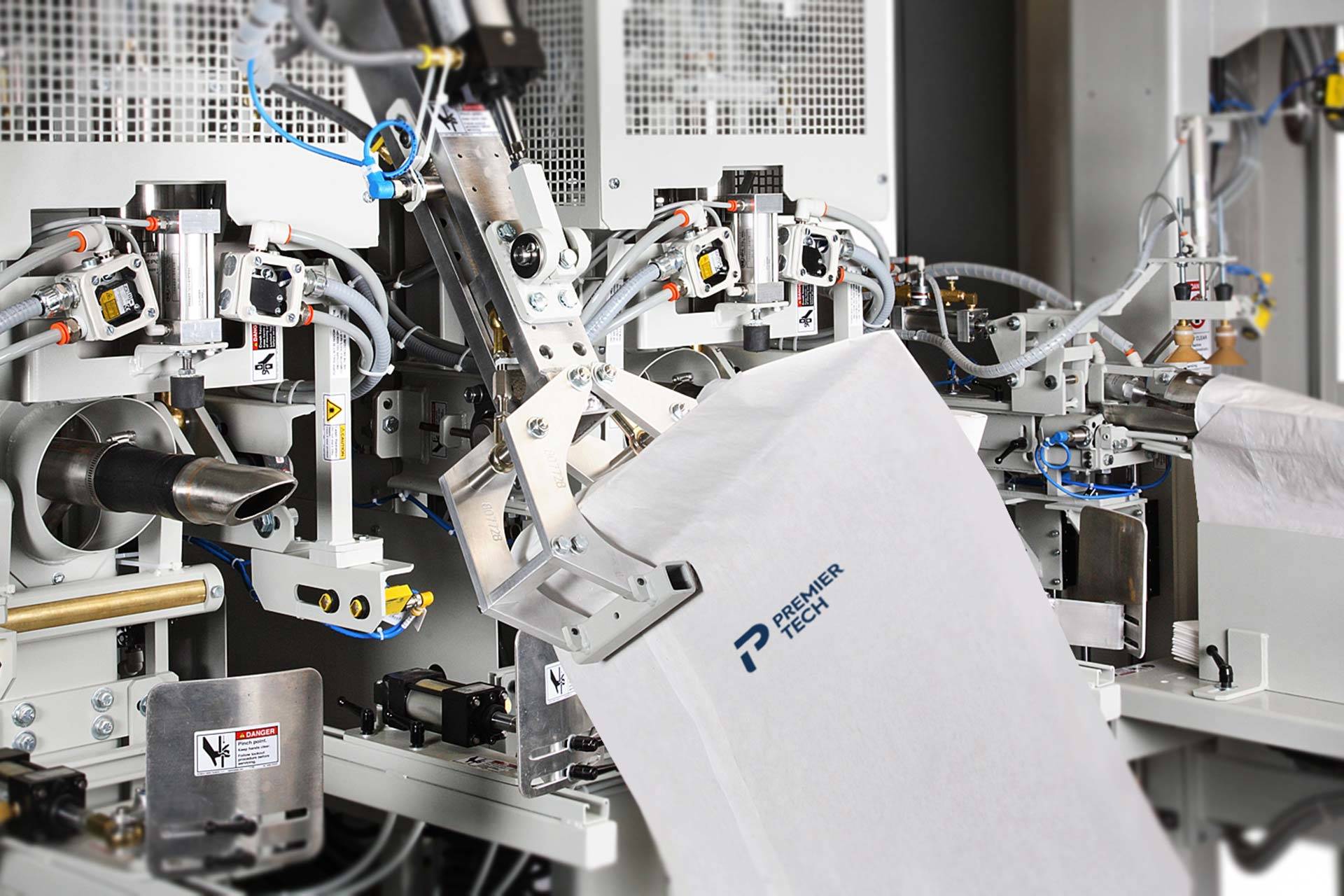

Premier Tech’s diverse range of valve bag packers are designed to be precise, efficient, and cost-effective for various materials. Tailored to the unique characteristics of your product, our semi and fully-automatic baggers are compact, low-maintenance, and aligned with your budget, space, and production needs.

With over a century of experience, we closely collaborate with clients in the food, chemicals, and minerals industries to optimize operations, covering bag handling, sealing, palletizing, and pallet wrapping.

How valve bag packers work

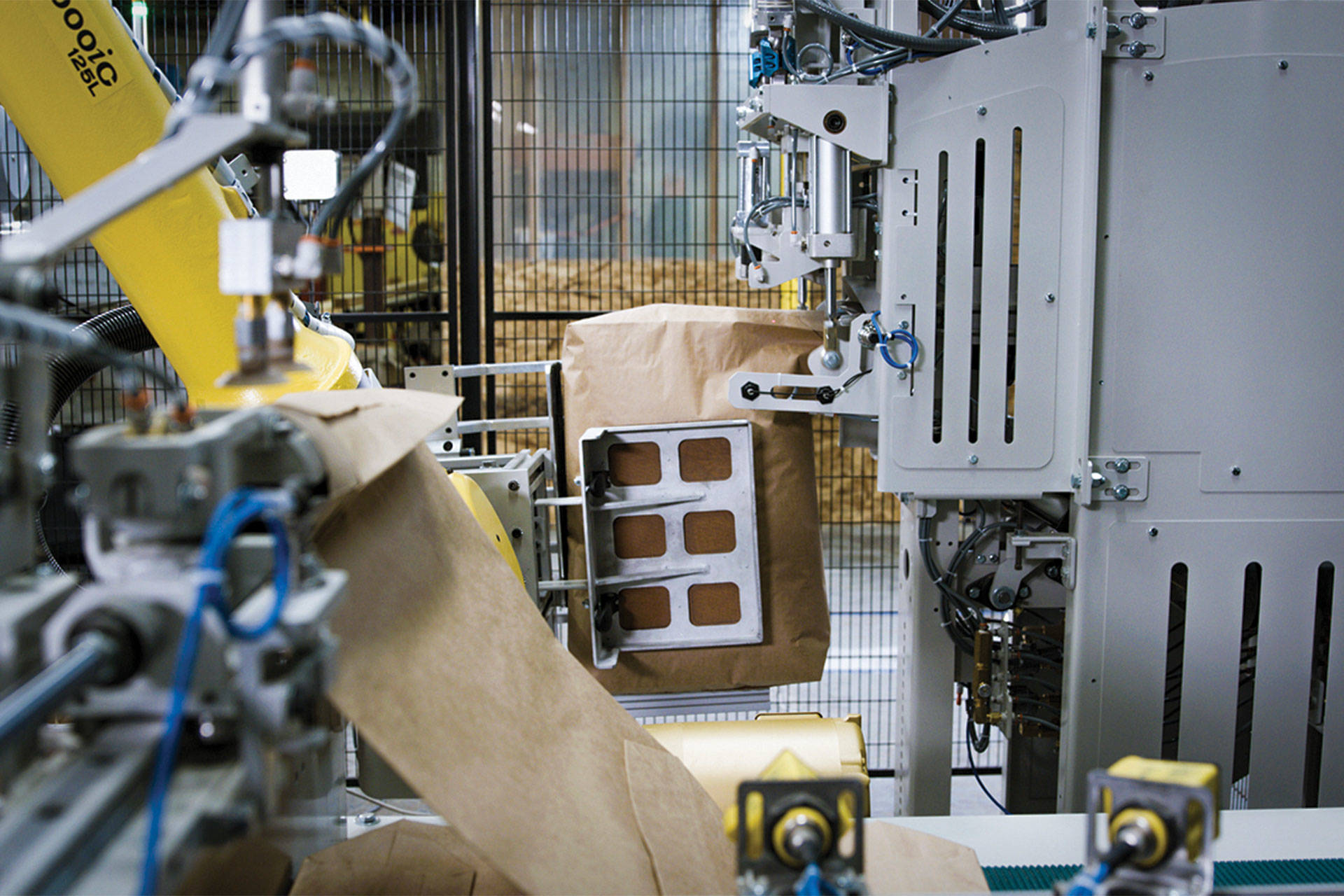

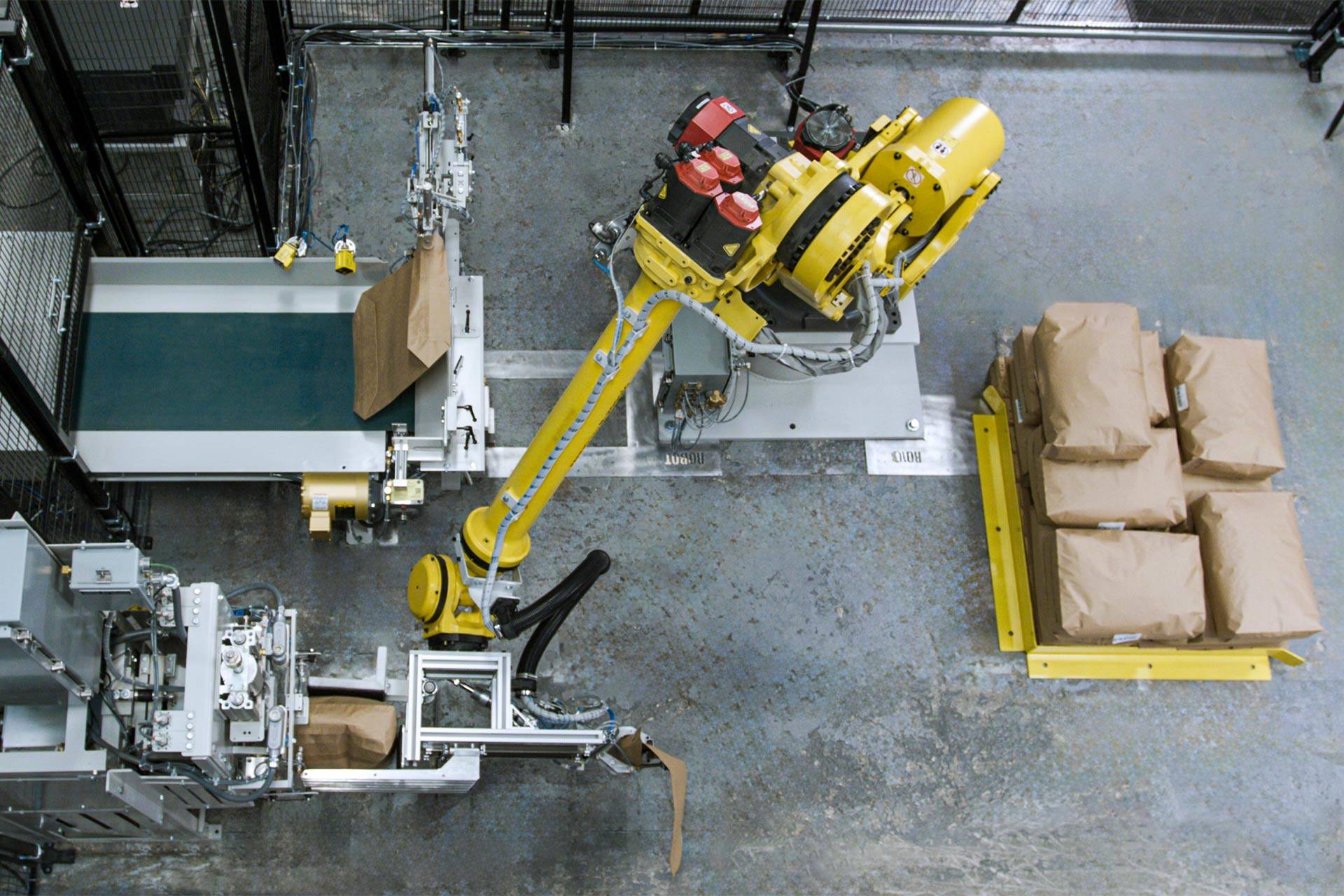

An operator, bag applicator, or robotic arm places an empty valve bag on the filling spout of the valve packer. The machine fills and discharges the bag when it reaches the target weight.

Bags can be sealed to ensure added protection and prevent leaks, contributing to a more stable and compact palletized load.

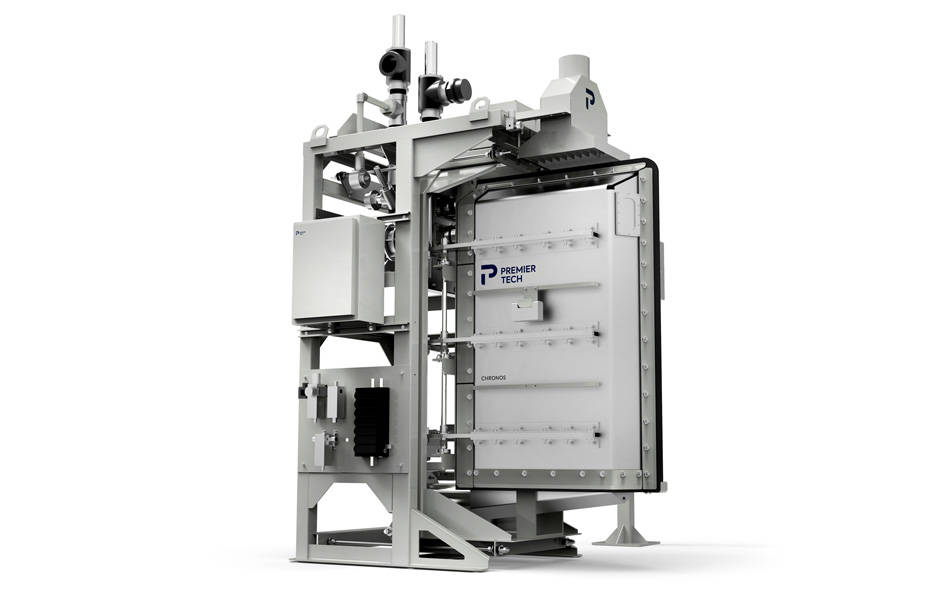

Our valve bag filling machines

What valve bag fillers can handle

Our valve bag packers can efficiently fill a variety of bulk materials, including powders, mixes, granules, and pellets, into 5 kg or heavier bags.

Many industries

- Food: bakery mixes, baking powder, cocoa powder, flour, dry milk powder, powdered sugar, starches

- Chemicals: ammonium chloride, carbon black, pigments, PVC, resins, and tricalcium phosphate

- Minerals: clay, cement and concrete mixes, gypsum, salt, lime, and, talc

Various product characteristics

- Abrasive

- Corrosive

- Dense

- Hazardous

- Light

- Sticky

- Volatile

Different filling rates

- High: up to 10 bags per minute (600 per hour)

- Moderate: up to 6 bags per minute (360 per hour)

- Low: up to 3 bags per minute (180 per hour)

Accurate filling

Valve bag packers excel in rapid and precise filling, thanks to the high accuracy of the dosing unit and weight controllers. This minimizes product loss and maximizes your ROI.

Extremely durable and reliable

The robust construction ensures decades of reliable, low-maintenance operations, supported by parts assistance. Whether you are familiar with us from St. Regis, Champion International, Stone Container, Smurfit-Stone, Altivity Packaging, Graphic Packaging, or STONEPAK, we have you covered.

Flexible configurations and automation levels

Our bagging systems also offer automated bag handling, sealing, and printing tailored to your packaging needs. Multiple valve baggers can be banked for added capacity, using conventional applicators and robotic bag placing and stacking for maximum efficiency.

Clean valve bagging technologies

Designed to reduce dust emissions and explosion hazards, our bagging solutions create a cleaner work environment, prioritizing employee health and safety.

They are also easy to clean and ideal for industries requiring hygienic packaging.

User-friendly control

Valve bag fillers are easy to use through the weight controller's interface or a master controller for the entire bagging system.

The simple touchscreen simplifies user management, editing, monitoring, and operation.

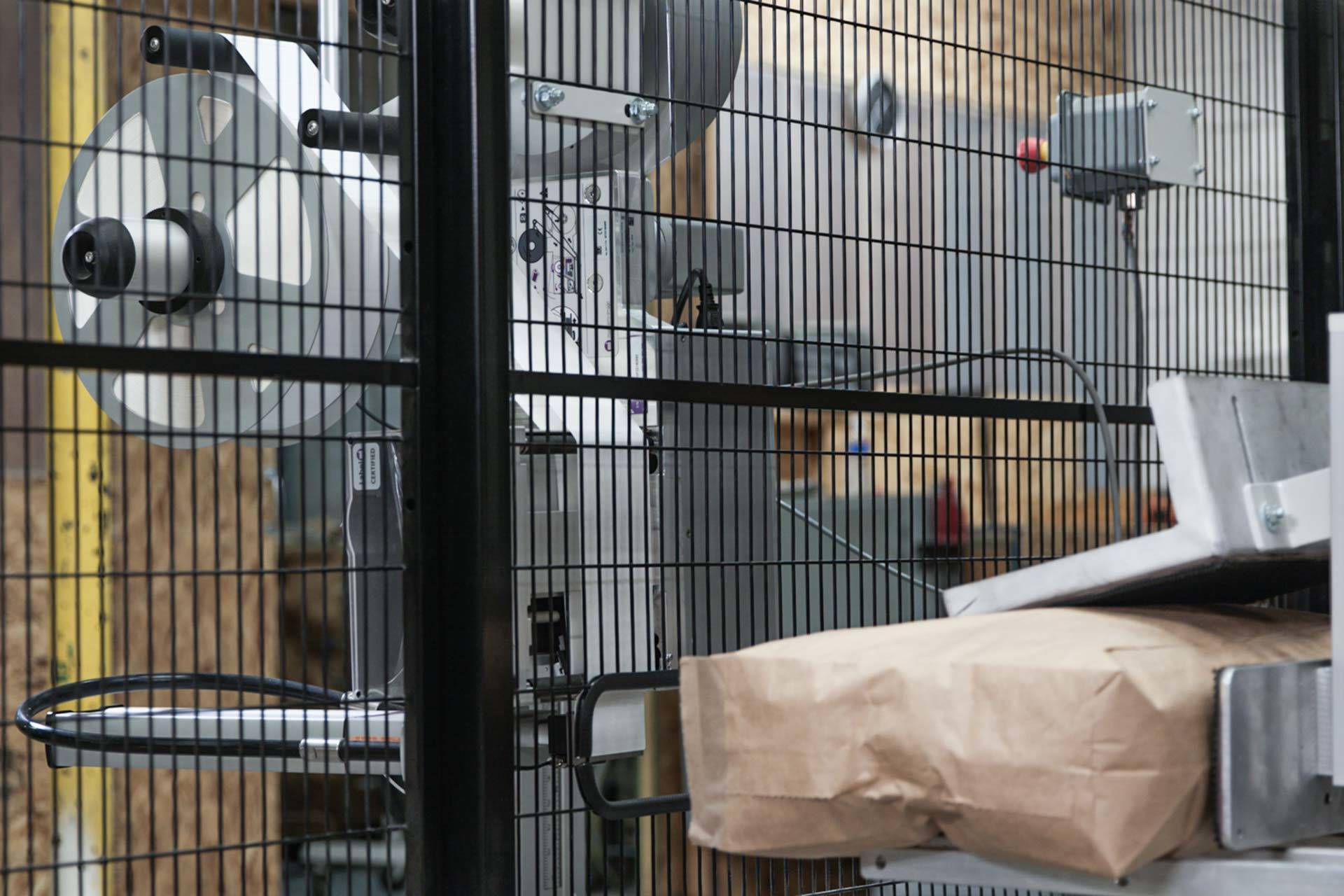

Held to the highest safety standards

Our automated bagging equipment come equipped with the latest in safety features:

- Dust collection and explosion protection

- Emergency-stops

- Light curtains

- Performance Level D compliance

- Safety fences with interlocking doors

- Safety guards or rails

Additional available features

We care about making your valve bag packaging equipment as functional as possible, offering a selection of integrations to meet your specific needs.

- Bag flatteners

- Conveyors

- Checkweighers

- Labelers and printers

- Metal detectors

- Operator seats

- Ultrasonic sealers

- Weight controllers

Get a quote

Tell us more about your project and we will send you recommendations and a free quote.

Lifecycle management

Personalized customer services to maximize your equipment performance and lifespan

Lifecycle management

Personalized customer services to maximize your equipment performance and lifespan

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Training

Practical operator training that ensures a smooth transition to automation

Training

Practical operator training that ensures a smooth transition to automation

Need help choosing the right valve bag fillers?

Request a quote

Tell us about your project, and we will reply with solution recommendations