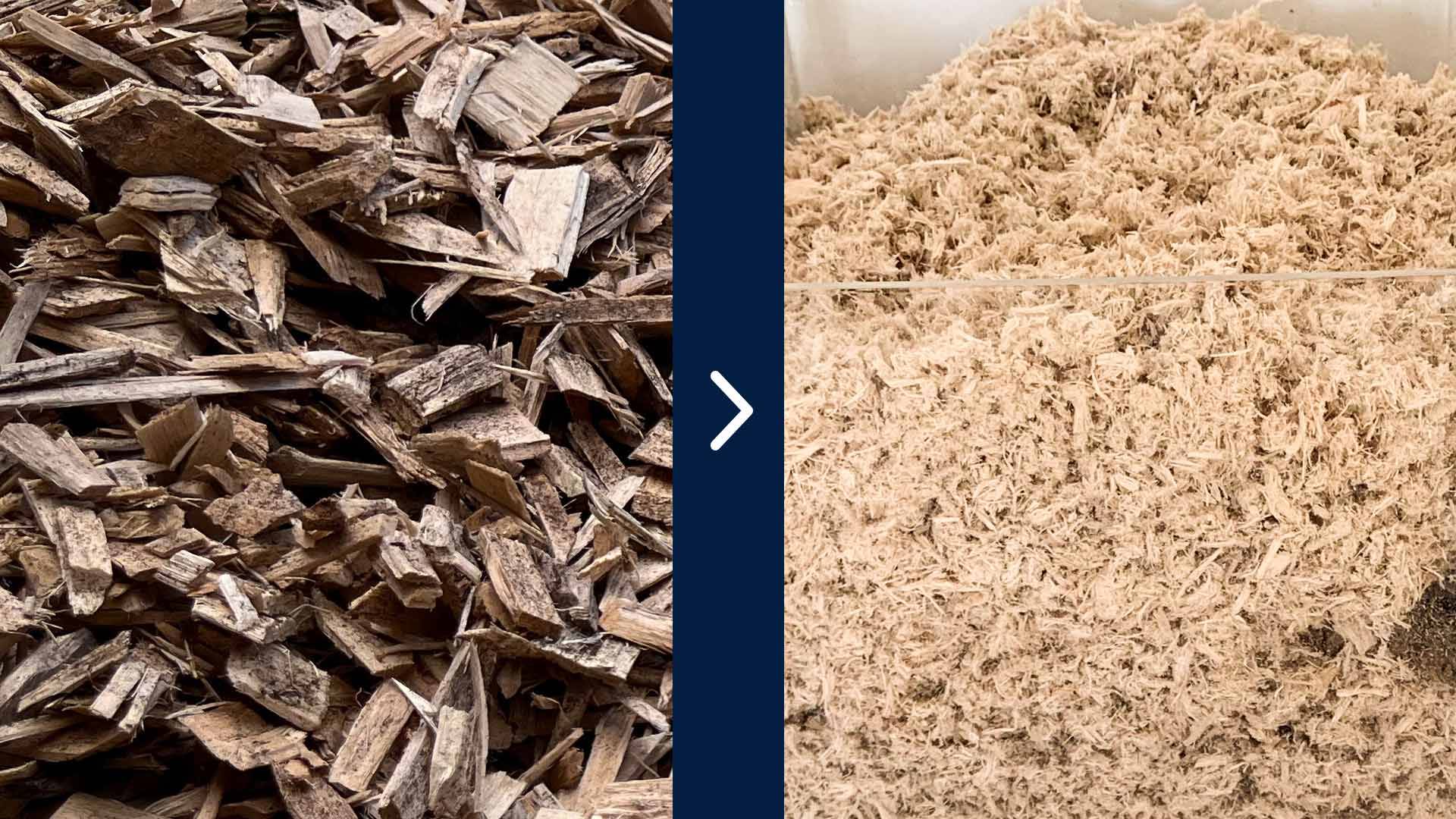

SLOOTWEG BPE SERIESWood fiber machine

Available in

Canada & USA, Europe and OceaniaThe SLOOTWEG BPE Serie wood fiber machine is a compact and energy-efficient processing equipment designed to produce structurally resilient fiber from various wood by-products.

The patented extruding and refining technology apply high pressure to the raw material, generating heat above 100°C. This process produces and sanitizes wood fiber, ensuring compliance with RHP certification standards.

This innovative technology allows substrate producers to add various kinds of local wood by-products as complementary or alternative raw materials in their mixes.

Capacity: up to 12 m3 per hour EN (16 yd3 per hour)*

Raw materials: white softwood chips, forest residues, compost wood

* Depending on the raw material

Features

Versatile

- Processes various wood by-products

- Adjustable to multiple fraction sizes, moisture content, and grades

- Produces different quality finished products, including fine, coarse, and colored wood fibers

Cost-effective

- Low-energy consumption

- Easy to operate and maintain

- On-site production with local raw materials

- Provides a short ROI and attractive TCO

Robust design

- High wear-resistant components, including hopper, housing, extruding screw, and refining plates

- Includes upstream safety screen and magnet for enhanced protection

- Reduces maintenance requirements

- Complies with CE, OSHA, and CSA safety regulations

Options

- Automatic top loader infeed to reduce labor costs

- Complete range of easily interchangeable extrusion matrices to obtain various fractions

- Dosing units for coloring fibers to meet specific customer needs

- Modular system allowing the addition of units to increase production capacity

- Temperature monitoring and logging to comply with RHP certification standards

White softwood chipsThey produce structurally resilient fibers with good water dispersion capacity

White softwood chipsThey produce structurally resilient fibers with good water dispersion capacity

Forest residueThey provide a wise use of by-products, reducing waste

Forest residueThey provide a wise use of by-products, reducing waste

Compost woodThe oversized material is transformed into a valuable alternative for soil use

Compost woodThe oversized material is transformed into a valuable alternative for soil use

Specifications

Typical equipment dimensions 4000 mm L x 2300 mm W x 2000 mm H (157.5" L x 91" W x 79" H)

Expansion ratio Up to 3.5 (depending on the material, moisture content, and matrix)

Recommended raw material fraction sizes Up to 50 mm

Power requirement Europe: 143 kW @ 400 V/3Ph/50 Hz

USA: 143 kW @ 460 V/3Ph/60 Hz