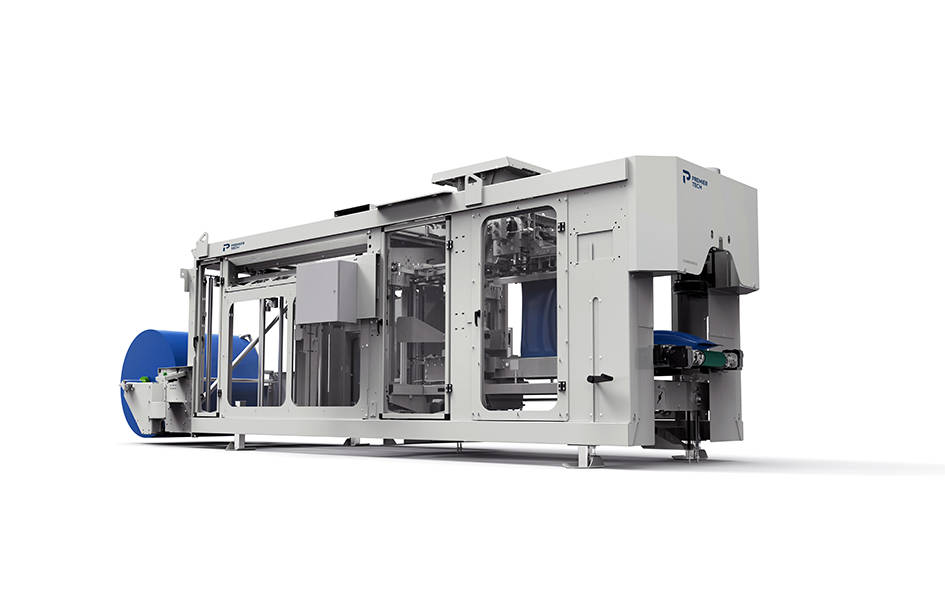

Form fill and seal bagging machines

FFS machines often remain the fastest, most efficient, and most economical way to package long runs of loose-fill materials.

Our portfolio features robust, high-speed FFS bagging machines that handle various bag sizes and bulk materials. Depending on your project's scope, budget, and required production rate, we can supply a bagger that enhances your packaging line's efficiency, capacity, and safety.

With expertise from our legacy brand, Chronos Richardson, and a global presence of over 350+ machines sold, we deliver automated packaging solutions tailored to your needs.

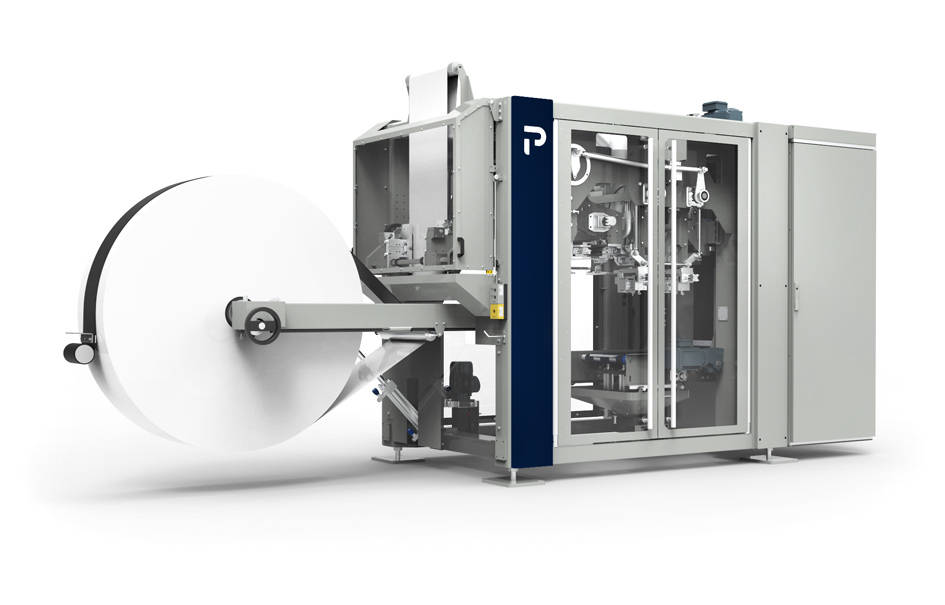

How does a form fill seal machine work?

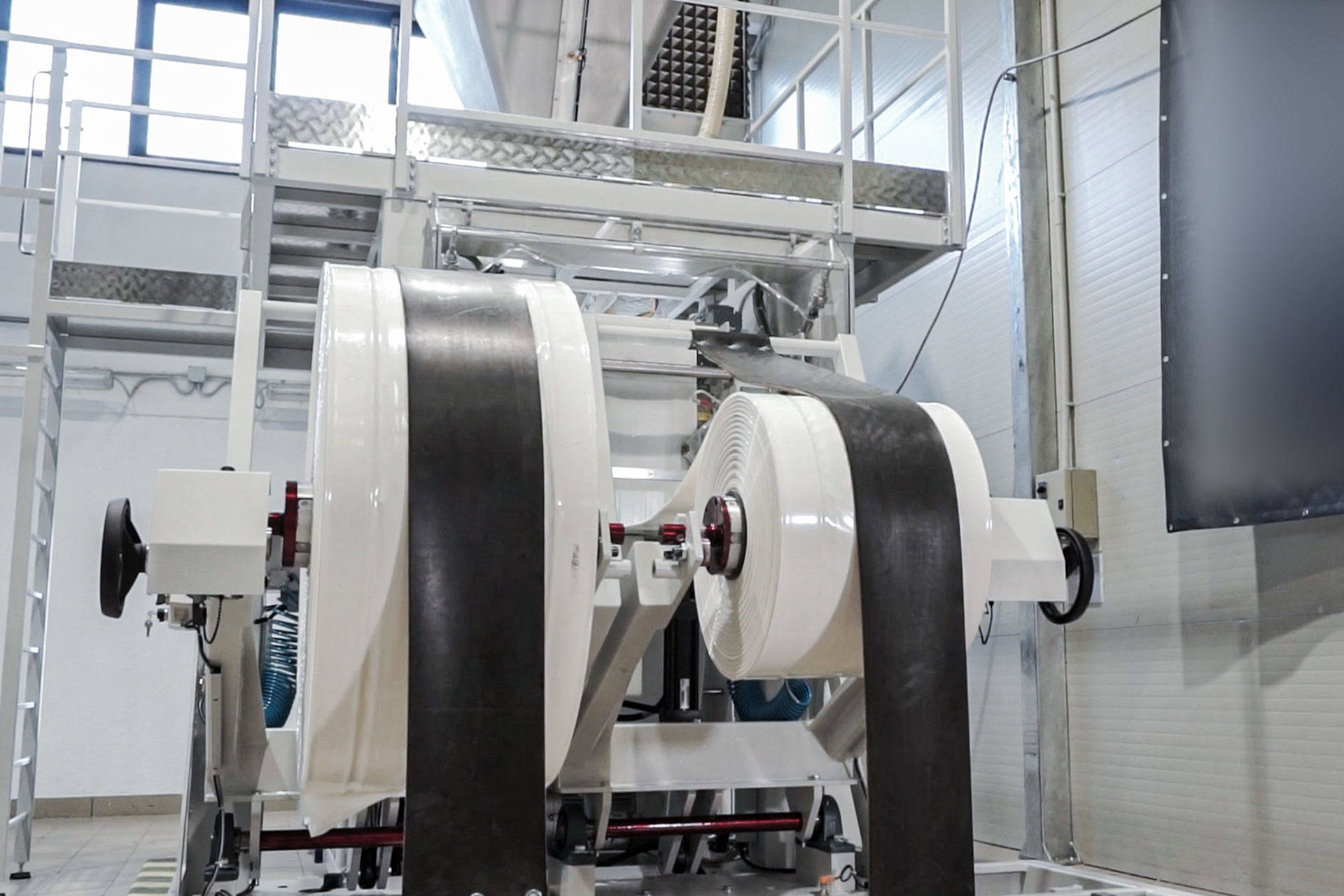

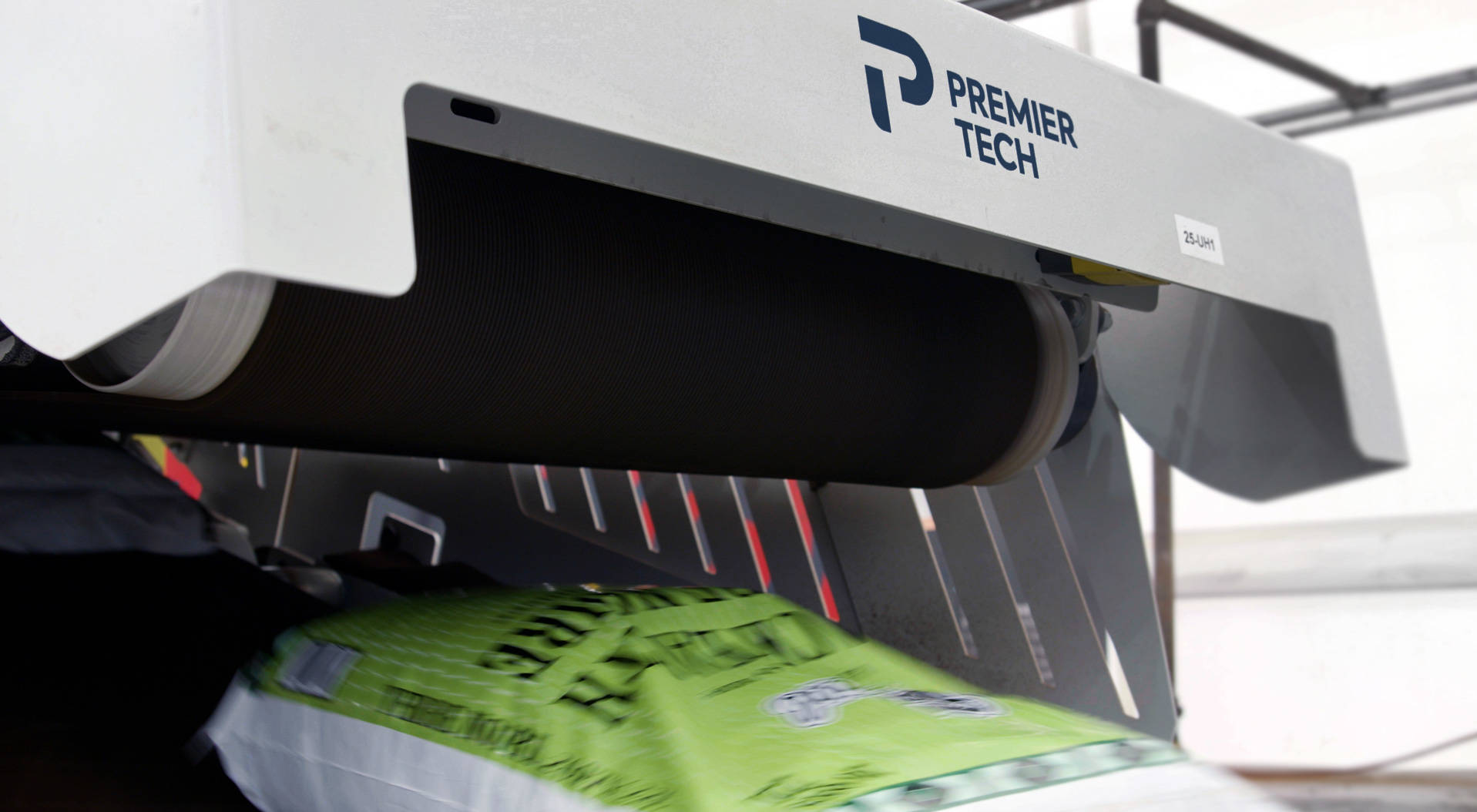

A form fill seal machine creates bags from plastic film, fills them with materials using a weighing scale or volumetric feeder, and seals and ejects them.

This continuous operation ensures streamlined packaging, making neat and attractive bags ready for palletization.

Our form fill and seal packaging solutions

Our automatic bagging machines are manufactured locally, with offerings varying by region.

What FFS bagging machines can do and handle

Our bagging machines efficiently package a wide range of free-flowing products into PE bags, accommodating weights from 0.5 to 3 cubic feet (4 to 85 liters).

Many industries

- Organics: bark, compost, mulch, soils, substrates, and wood pellets

- Minerals and chemicals: cat litter, fertilizers, rock, salt, and sand

- Nutrition: rice and sugar

Wide range of bags

- Pillow-type

- With bottom gussets

- With bottom corners

- Small and big formats

Various speeds

- High: up to 35 bags per minute (2000 per hour)

- Moderate: up to 20 bags per minute (1200 per hour)

- Low: up to 5 bags per minute (300 per hour)

Versatile bagging solution

Our form fill and seal baggers offer easy reel changes for different bag sizes and formats. With their many customization options, they create compact, highly durable, and visually appealing bags.

- Bag top trimmer

- Embossing or dry ink coder

- Gusset former to create a fold at the bottom of the bag

- Corner sealer to strengthen the bottom of the bag

Cost-effective bagging solution

Form fill seal machines effectively reduce packaging costs by removing the need for pre-made bags. With exceptional performance and reliability, they offer an economical packaging solution.

Precise and reliable filling

Top-of-the-line volumetric feeders and bagging scales achieve precise measurements of various products. They balance speed and dosing precision, optimizing efficiency and maximizing profitability.

Dependable bagging operations

Robust construction and durable components ensure dependable, long-lasting performance.

Comprehensive technical support and spare parts specialists enhance operational reliability and serviceability.

Intuitive and easy to operate

Our FFS machines feature PLC control and an intuitive HMI.

Operators can efficiently perform product or recipe changeovers and address slowdown factors, optimizing uptime.

Held to the highest safety standards

Our bagging lines come equipped with the best safety features to protect your employees:

- Safety doors with trapped key interlocking

- Safety fencing to prevent access to moving parts

- Emergency -stop buttons

- Dust removal system

Additional available features

We care about making your packaging line as functional as possible and offer a selection of integrations to meet your specific needs.

- Conveyors

- Bag flattener

- Check weigher

- Metal detector

- Labeler and printer

- Built-in connectivity for 4.0

Get a quote

Tell us more about your project and we will send you recommendations and a free quote.

Lifecycle management

Personalized customer service to maximize your equipment performance and lifespan

Lifecycle management

Personalized customer service to maximize your equipment performance and lifespan

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Operator training

Practical operator training that ensures a smooth transition to automation

Operator training

Practical operator training that ensures a smooth transition to automation

Need help choosing the right form fill seal packaging equipment?

Request a quote

Tell us about your project, and we will reply with solution recommendations