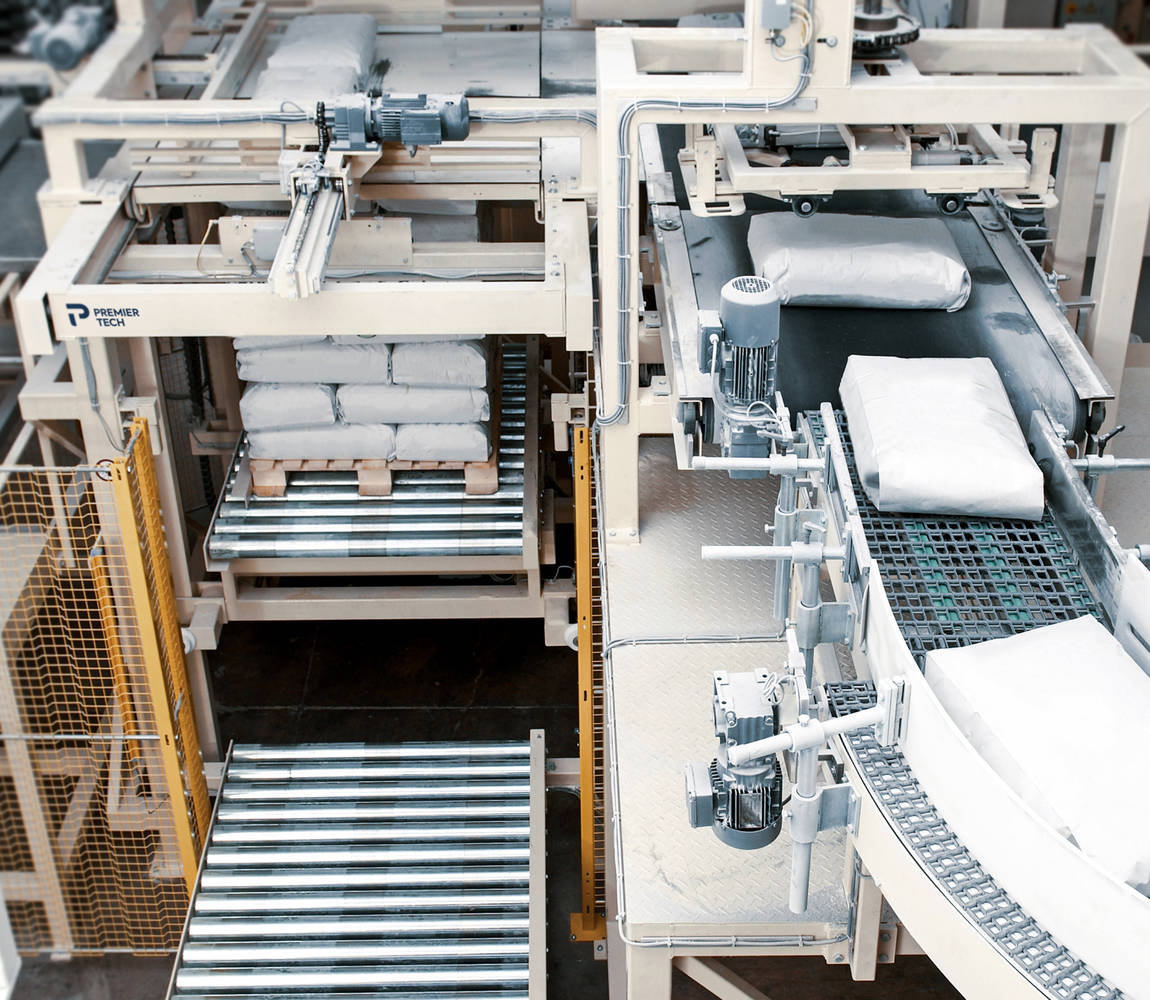

Palletizing equipment

Whether you want to increase your production capacity, improve working conditions and safety standards, or replace older units, Premier Tech is ready to respond with a machine that suits your needs.

We offer state-of-the-art, reliable palletizing systems, including robotic, conventional, and cobot solutions, for various types of containers. Plus, our equipment can be adapted to various environments, whether cold, hot, harsh, or dusty.

Our expertise is founded on our concern not only for the safe and secure packing of products, but ultimately our desire to help customers reach their business goals.

What automatic palletizers can do and handle

Our machines efficiently create optimized, stable, and consistent loads to protect your goods during transport or storage.

All type of containers

- Bags: bags, bales, and bundles

- Cases: cases, cartons boxes, totes, and trays

- Other: bottles, cans, and jugs

Every industry

- Nutrition: food and beverages, animal feed, and pet food

- Organics: forestry, and lawn and garden

- Industrial: minerals, chemicals, and building materials

- Agriculture: seeds and crops

Speeds

- Bags: up to 40 per minute (up to 2400 per hour)

- Cases: up to 80 per minute (up to 4800 per hour)

Palletizing technologies

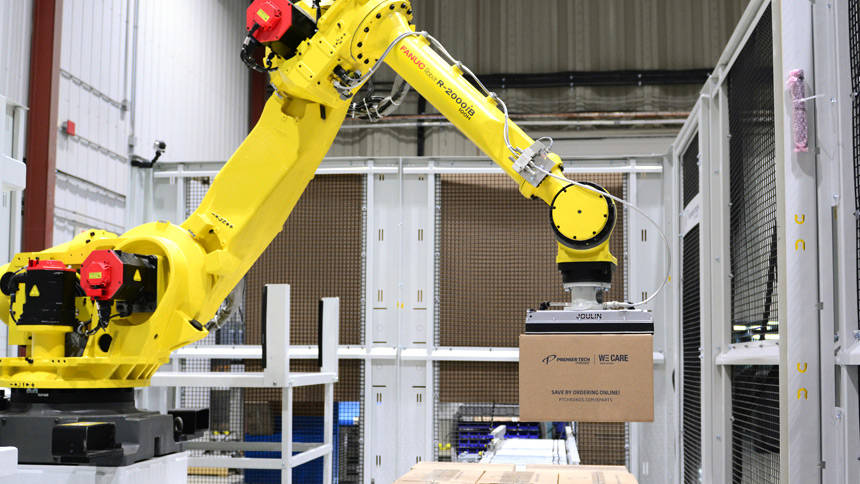

Robotic palletizers

Highly efficient and safe, our robotic palletizers can handle multiple SKUs and be adapted for various speeds and levels of automation.

Ideal for low to medium production capacity, they are known for high uptime and superior reliability.

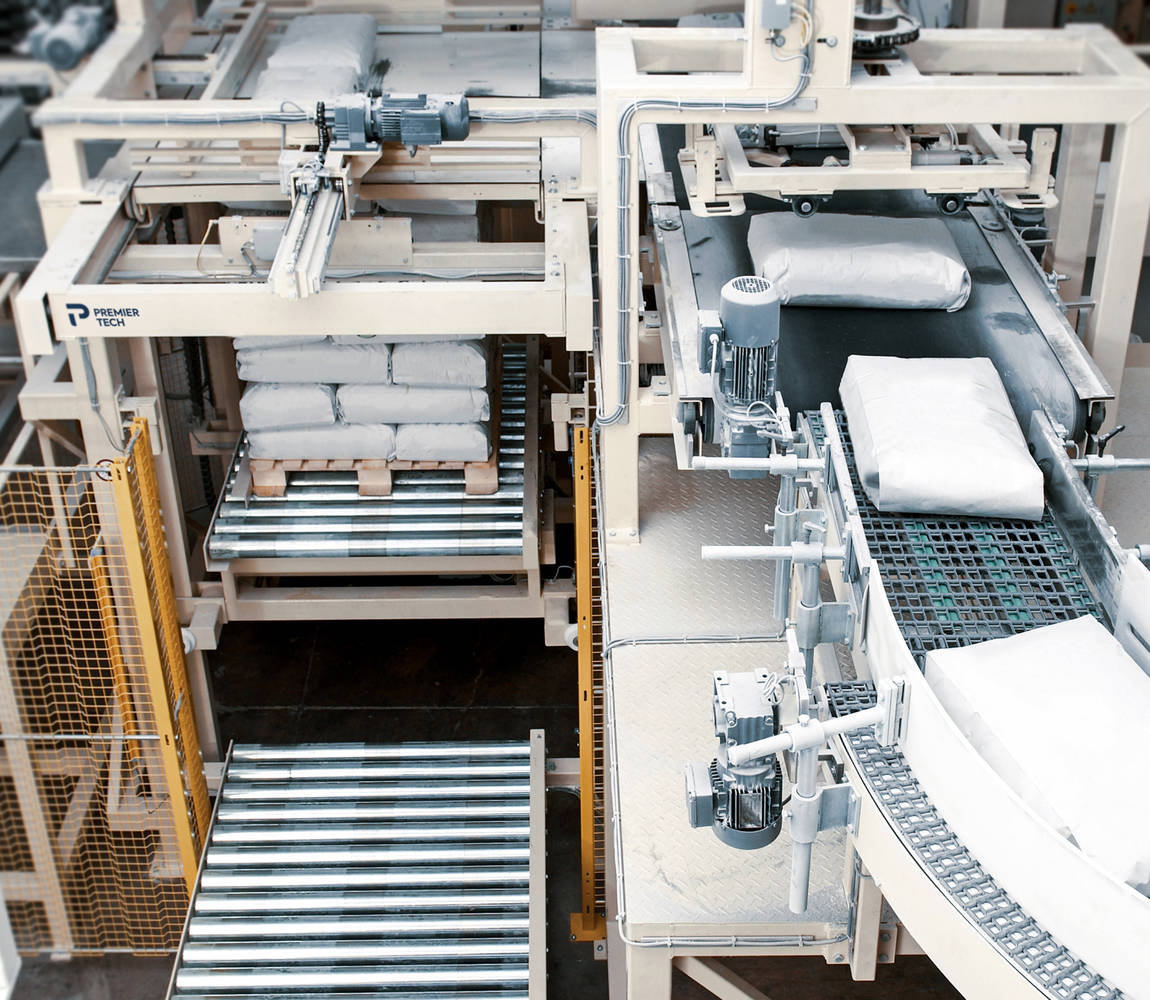

Conventional palletizers

Our conventional palletizers are ideal for high-speed and high-volume operations with long production runs of the same product.

They are extremely safe and consistently produce stable, square, and high pallets.

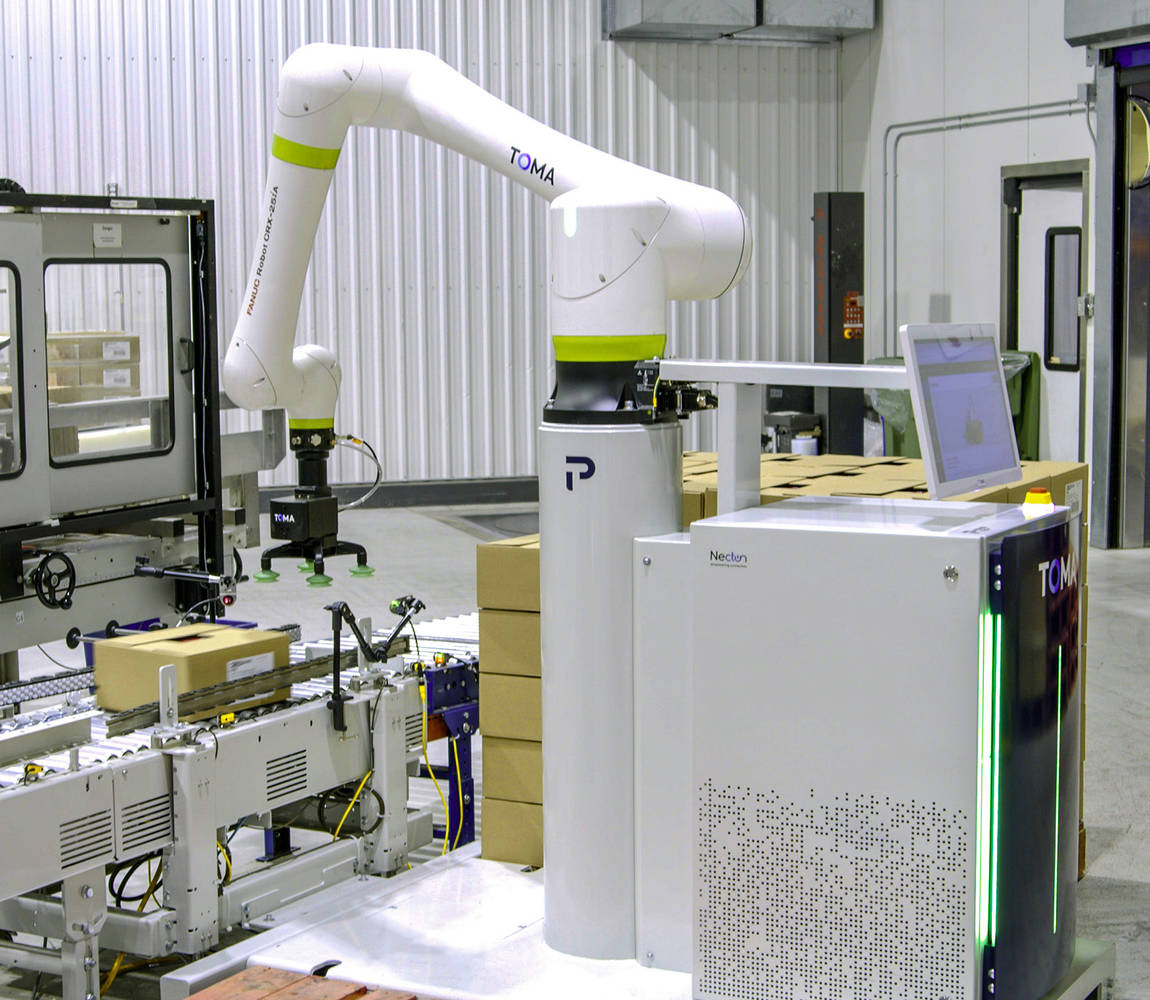

Cobot palletizers

Our cobot palletizers offer a safe and easy-to-use solution for palletizing rigid products.

They are highly moveable and adaptable, ideal for sectors with low production requirements, seasonal variations, or new product lines without a major equipment switch.

Wondering how to choose the right palletizing system for your business?

Are robotic, conventional, or cobot palletizers best for your operations? Knowing how many products you handle and what production rates you need to reach will help you select the appropriate technology.

| Technologies | Robotic palletizer | Conventional palletizer | Cobot palletizer |

|---|---|---|---|

| Applications | Can handle virtually any type of product including bags, cases, pails, and drums | Can handle bags, bales, cases, boxes, trays, and other rigid containers | Can handle rigid items like cases and pails |

| Speed and SKUs | Multiple SKUs at lower speed | Single SKU at higher speed | Multiple SKUs at low speeds |

| Versatility | High flexibility

| Limited flexibility

| High flexibility

|

| Maintenance and training | Low maintenance, but requires more specialized training | Slightly more maintenance, but simpler to perform | Simpler and infrequent maintenance, with minimal employee training |

| Footprint and modularity | Similar footprint than conventional equivalent, but more modular and flexible depending on desired level of automation and plant layout | Similar footprint than robotic equivalent, but limited modularity | Smaller footprint due to integrated safety features and fewer components |

| Price | Varies mostly depending on the desired level of automation, type of product handled, and speed | Varies mostly depending on desired speed | More affordable than robotic and conventional palletizers |

How we partner in your success

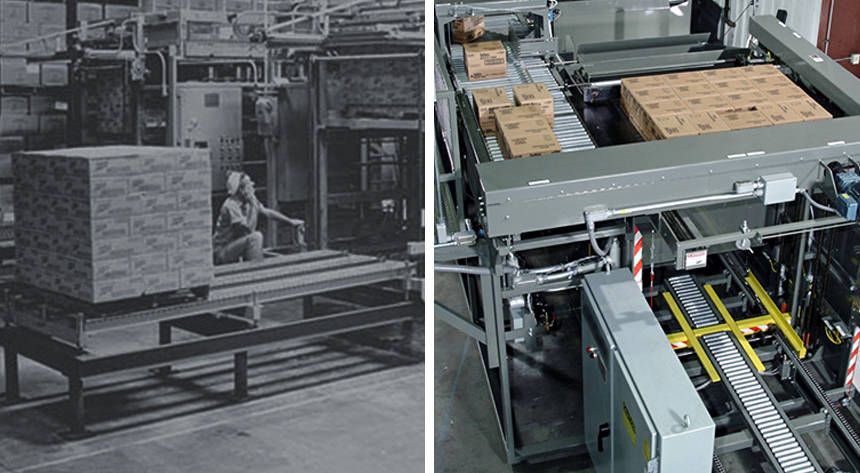

With over six decades of expertise and the combined strength of numerous legacy brands such as vonGal and Chronos Richardson, Premier Tech has gained a reputation for providing outstanding, high performing automated palletizers.

Partners all along

Partners through the entire process, from consulting and engineering to installation and training services.

Testing before shipping

Rigorous system testing before shipment plus full installation and final system acceptance testing on-site.

Leading-edge equipment

Innovation, research, and development are some of our key values, inspiring the design of leading-edge machines

Our customers

We specialize in equipment and client solutions for nutrition, agriculture, organic and industrial products. Here are some of the customers we’ve been privileged to serve.

Complete your packaging line with pallet wrapping

Our range of palletizers can come as standalone equipment or complete lines. Ensure that your goods arrive safe and secure, while also protecting them from environmental risks.

Streamline your workflow with

Automated bagging machines

Our versatile bagging machines can handle open-mouth, valve, compression, FIBC, and form, fill and seal bags.

Automated bagging machines

Our versatile bagging machines can handle open-mouth, valve, compression, FIBC, and form, fill and seal bags.

Case packing machines

Reduce labor costs and increase productivity with one of our pre-engineered or customized robotic case packing solutions.

Case packing machines

Reduce labor costs and increase productivity with one of our pre-engineered or customized robotic case packing solutions.

Learn more about palletizers

Need help or have a question?

Request a quote

Tell us about your project, and we will reply with solution recommendations