How Leading Palletizers Have Stood the Test of Time

Here’s a wild guess: you have a car, your father had a car, and your grandfather had a car. When you compare these three cars, the common ground is that they all took you from point A to B.

Now think of what your car does today versus your grandfather's 60 years ago. The same logic applies to conventional palletizer machines. As technology evolves, the best conventional palletizers should too.

To better appreciate how modern equipment manufacturers have engineered today’s conventional palletizers for maximum speed and efficiency, let’s take a closer look at the development of current design features including:

- Speed

- Ease of use

- Simple maintenance

- Safety

Conventional palletizers may have been around for quite some time, but they are far from being outdated. And even though robotic palletizers can seem more modern or trendy, conventional palletizers often remain a reliable and durable choice. Here’s why they’re still at the top of their game.

Significant developments in conventional palletizing

Speed

Conventional palletizers often remain the fastest way to accomplish end-of-line operations and have become even faster thanks to technological progress.

Since they don’t rely on the movement of a single arm-tool, they can reach higher execution speeds. The accumulation of product on the conveyor ensures continuous processing for maximized operations.

Ease of use

Operator interaction within conventional palletizing systems has become much simpler over the years.

Quick and easy product changeovers

Long production runs of the same product are perfect for conventional palletizers. These days however, it is also possible to handle different SKUs with a conventional solution.

A conventional palletizer’s HMI allows for quick and easy automatic product changeovers. These controls have predetermined settings in stored recipes to adapt when alternating products. Such parameters establish which pattern the conventional palletizing machine will obey for accurate palletizing.

Effective troubleshooting

Two-way feedback is now possible within a conventional palletizing system through data extracted from the HMI. Plus, information on production rates, downtime, maintenance requirements and fault messaging are now easier to gather and analyze for improved packaging efficiency.

Troubleshooting is also much simpler thanks to the ability to monitor input and output status of sensors and controls directly on the screen. If, for example, a machine cycle exceeds the established timeframe, or an unexpected condition occurs, timers or sensors will signal the programmable logic controller (PLC) to stop the machine. Fault messaging will then appear on the HMI explaining what went wrong so it can be assessed rapidly.

Preventive maintenance is also made easy with quick on-screen messaging.

Finally, today, PLCs and HMIs are tied into overall plant networks through secure VPN communications or routers. This allows remote access to the palletizer for troubleshooting and service. A supplier who offers a full dedicated customer care service is equipped to assess situations as they occur.

Simple maintenance

Nothing new here: Downtime is non-productive. The good news is that significant progress has been made toward the reliability of conventional palletizing.

Today’s conventional palletizers require less maintenance and when they do, internal servicing is easier to manage. Current machines are manufactured with fewer chains and sprockets, which requires overall less monitoring over time.

Where direct drives are not effective, polychain belts are favoured since they require less care and do not require lubrication. Most motors are driven by a variable-frequency drive (VFD), allowing the operation to ramp up or ramp down speed smoothly. A VFD not only removes stress from the equipment but ensures gentle handling of the product.

Even though conventional palletizers do operate with more pieces than their robotic counterparts, the repair costs are lower thanks to the ready availability of replacement parts from local suppliers.

Further, wearing surfaces are now made from ultra-high-molecular-weight polyethylene (UHMW) instead of steel. UHMW has a high level of shock-resistance, and its low friction coefficient allows it to slide easily on metallic faces. It is easy to change and costs less to replace.

Safety

Over the years, the manufacturing industry has shifted in terms of safety priorities, and this is a big win for plants of all kinds. Back in the day, operators could approach the equipment without proper guarding. Conventional palletizers now include advanced safety features to prevent injuries.

Fences

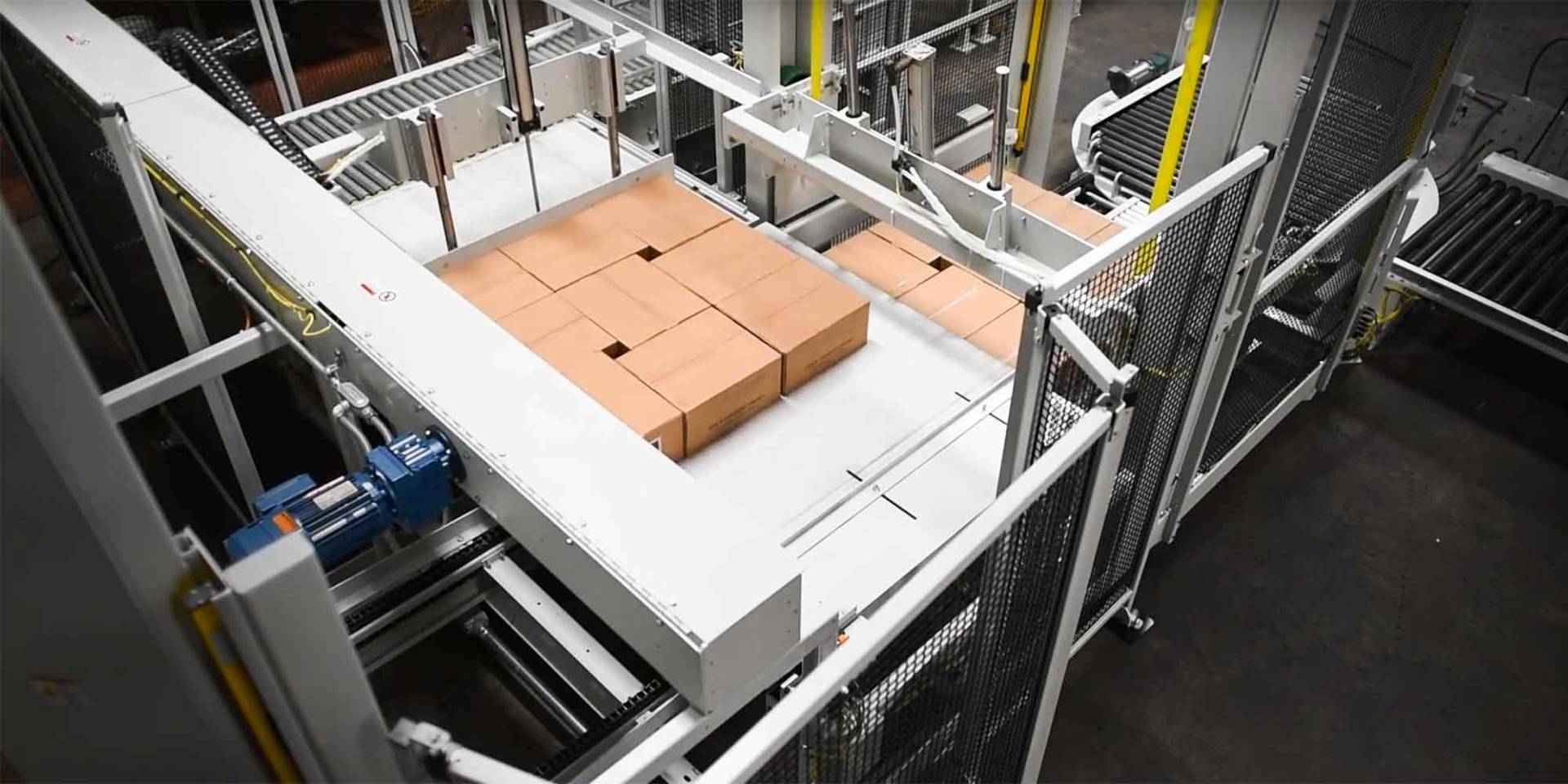

The palletizing machine is safeguarded by fences.

Trapped key interlocking

The doors and gates have trapped key interlocking. This feature creates a safe sequence if a person enters the perimeter of the equipment.

For example, the key assigned to the power source will also be used to access high-risk areas. Once the door is opened, the key will be trapped until it is closed again. A secondary key follows the operator into the fenced area. The equipment can’t be reinitiated without both keys in their proper place.

Light curtains

The presence of light curtains creates safety perimeters between humans and the machine. If a person approaches the palletizer, the light beam will detect them and immediately put the machine in a safe condition.

Handrails

Handrails are installed on top of the equipment to reduce the risk of injury when performing maintenance operations. Air dump valves are also in place so that if any stop is initiated, no stored energy remains in the palletizer.

Brakes and shafts

Conventional palletizers are now equipped with safety brakes and shafts if operations are interrupted while the hoist is up. This feature prevents unexpected movements while performing maintenance or repositioning pallets or products in the hoist area.

Different user access

The equipment owner now has better control over which team members can access different levels on the machine. Functions on the HMI touchscreen allow for adjustments to be made without entering the electrical panel. Since a maintenance technician is more likely to need access to the entire machine than an operator, different passwords can be generated for specific actions.

Conclusion

Some things aren’t made to change in conventional palletizing. As in the 40s, manufactured goods still go through the infeed, onto the conveyor and wind up on a pallet at the end of the day.

However, although the basic principles remain the same, technology in this field has evolved over the past years. It now meets the ever-growing complexity of the market–and the best palletizer manufacturers are on top of this.

Boost your packaging operations

Whether you're looking to increase production capacity, replace older units, or improve working conditions, Premier Tech is ready to respond with a state-of-the-art palletizing machine that suits your needs.