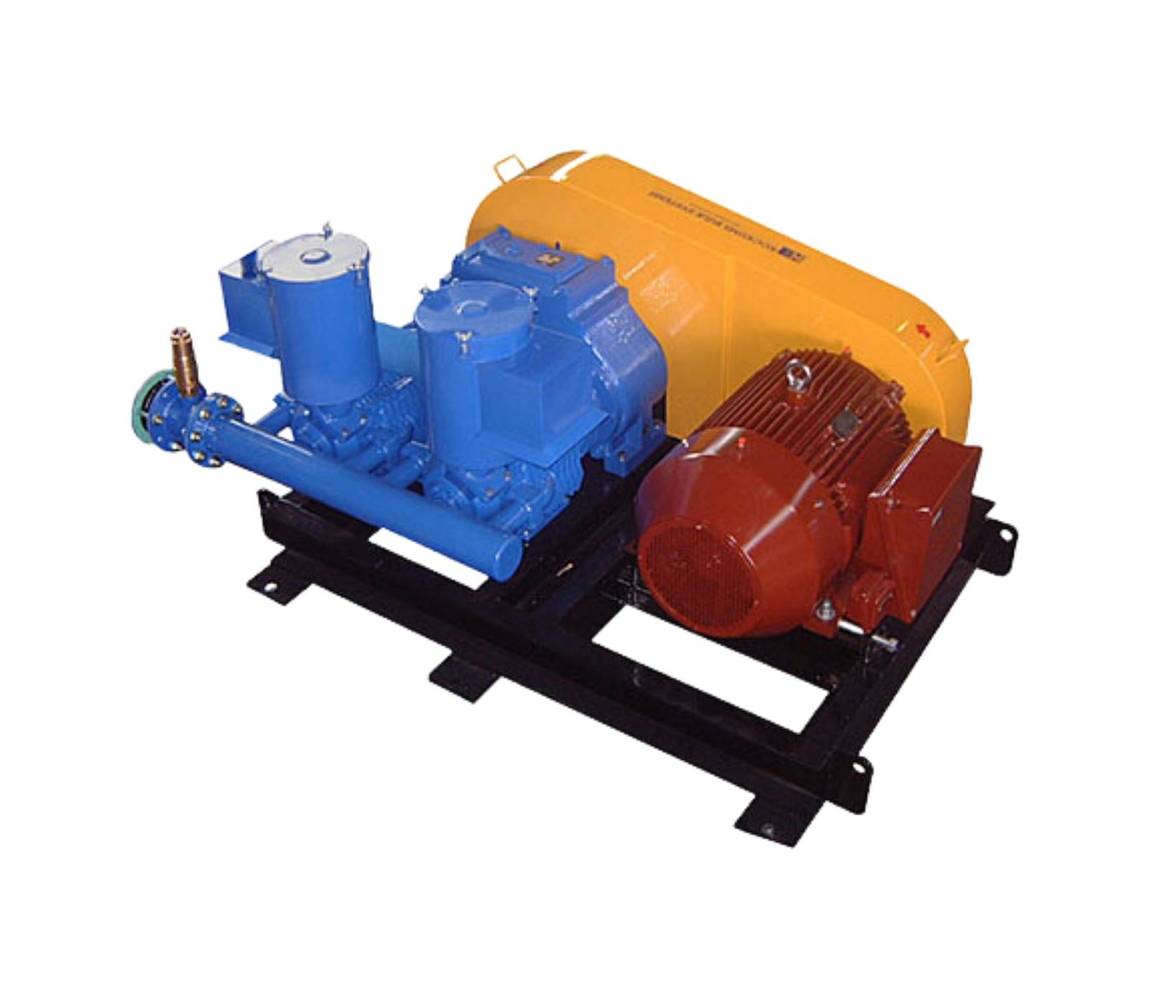

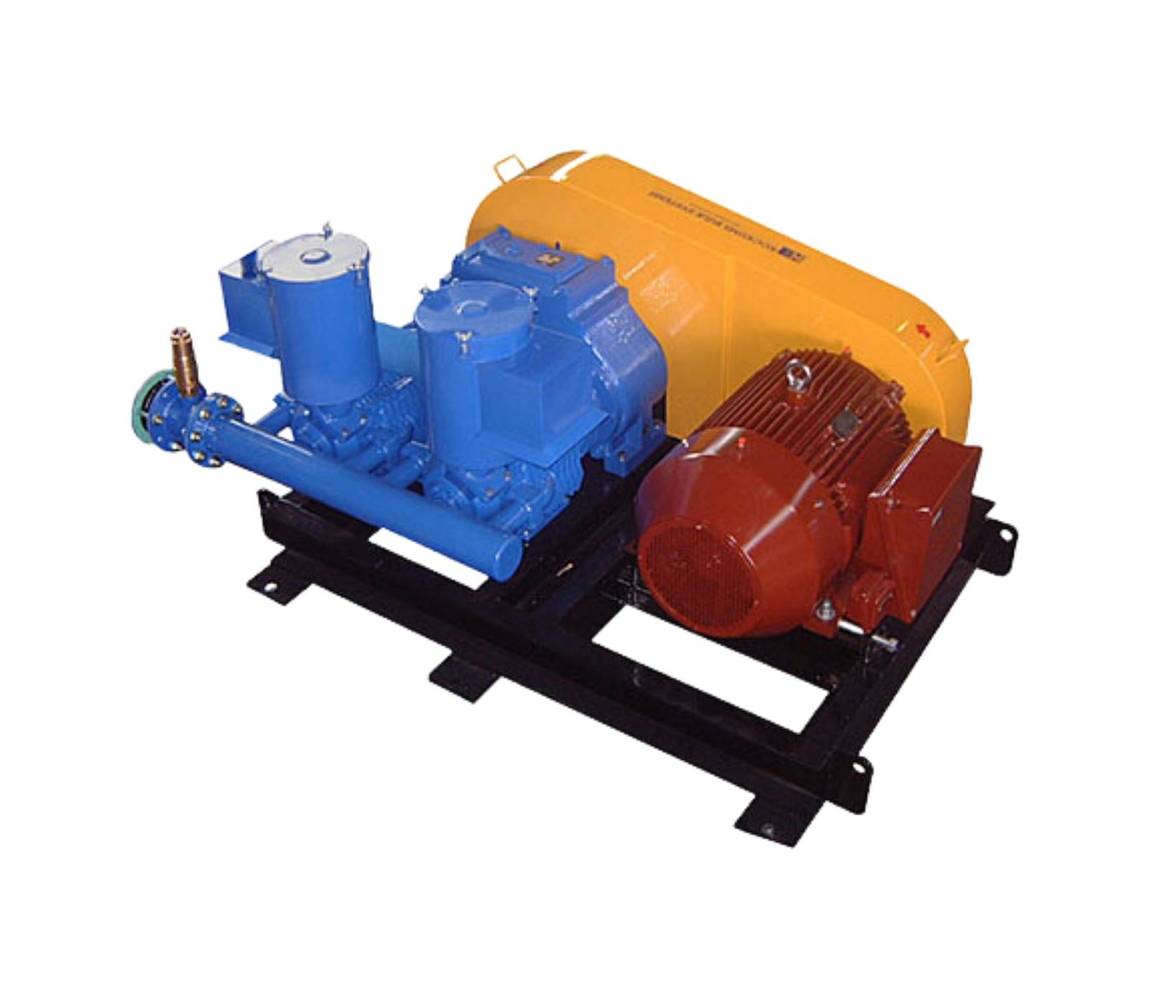

KOCKUMS HORI SERIES

Wing compressor

Available in

Asia, Canada & USA, Latin America and OceaniaWing Compressors efficiently unload dry bulk tankers and in-plant conveying systems. They are designed to operate continuously at a maximum pressure of 200kPa, achieving optimal efficiency with dense-phase pneumatic conveying.

The discharged air's relatively low pressure and high temperature prevent the dew point from being reached, so the air stays dry. No expensive air-drying equipment is required, unlike other compressors, such as high-pressure screws.

These compressors offer a unique combination of low energy consumption, solid performance, and extreme durability.

How they work

Wing compressors function entirely differently from conventional reciprocating-type compressors. Their standout feature is the rotor's unique rocking motion rather than the more traditional rotation in the cylinder.

During each cycle of the rocking motion, gas is sucked in and discharged through reed valves in separate sectors of the circular barrel.

Bulk materials: powders

Features

Performance

- Highly efficient wing generates maximum airflow with minimal energy consumption

- Low temperature of the air outlet

- Low-noise emission during operation

- Oil-free air ideal for handling food-related products

Heavy-duty design

- Simple, rugged, and reliable construction suitable for high-duty remote locations

- Low rotational speed (RPM) for ease of direct drive at low engine speeds

- Maximum operating pressure of 2½ bar gauge, enabling the tanker to handle high-pressure applications

Cost-efficiency

- Designed specifically for conveying duties, making it economical

- Avoids wastage that usually occurs when serving multiple air consumers