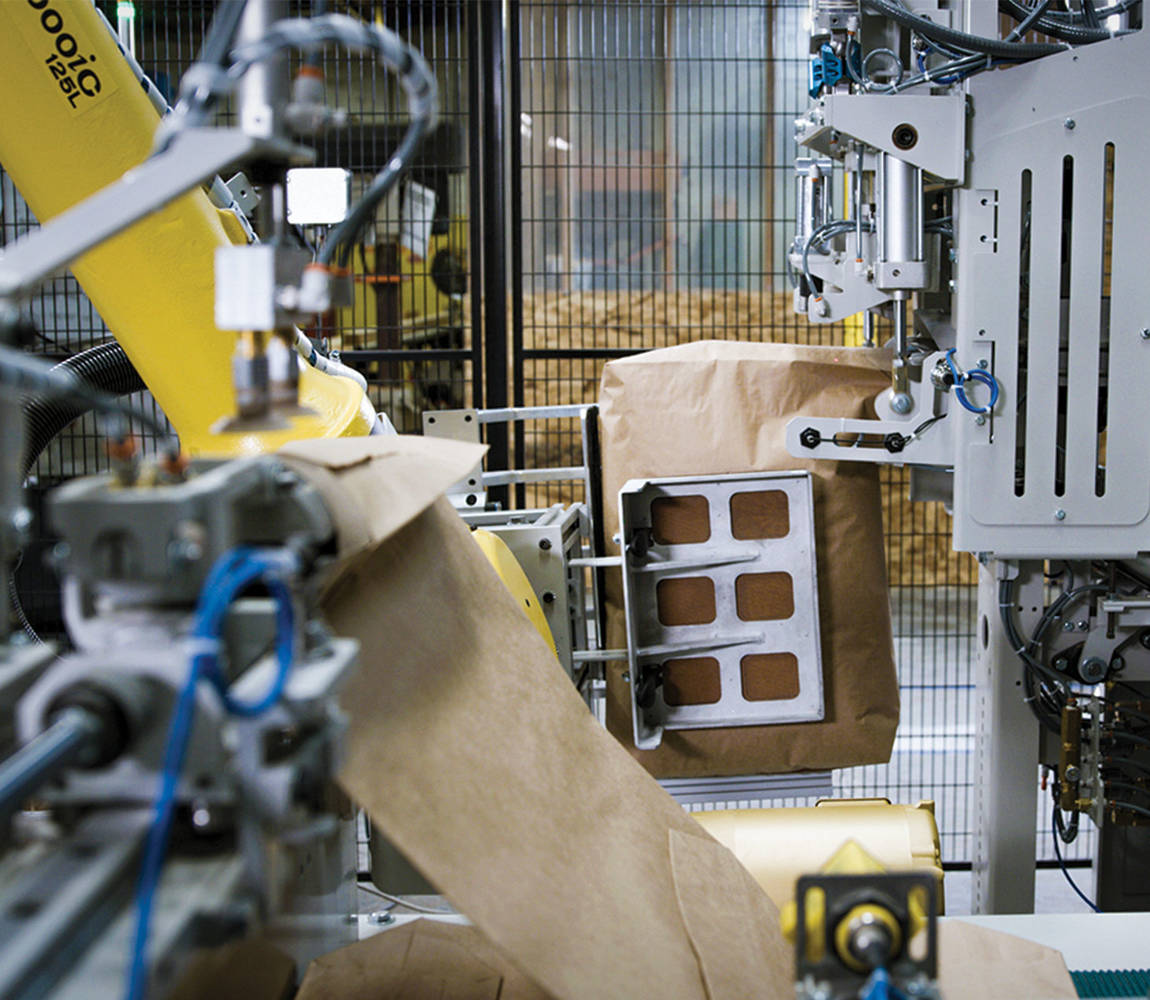

CHRONOS APPLY AND STACKRobotic valve bag applicator and palletizer

Available in

Africa, Asia, Canada & USA, Europe, Latin America and OceaniaThe Apply and Stack is an automatic valve bag placer and palletizer that can complement any air, auger, or impeller valve bag fillers.

The robotic system offers increased reliability and consistency while featuring a compact, modular, and economical design.

The versatile bag handling equipment suits factories with lower production rates seeking to automate manual packaging operations.

Speed: up to 2 bags per minute (120 per hour)*

Bulk materials: powders and granules

Bag materials: paper, woven polypropylene, and polyethylene

Bag types: valve (left-hand and right-hand)

Bag weight: 11 to 110 lb (from 5 to 50 kg)

* If sealing is required, rates are up to 2.5 bags per minute (150 per hour).

Features

Performant all-in-one equipment

- Places empty valve bags on the filling tube and stacks filled ones directly on a pallet

- Equipped with a durable and low-maintenance FANUC robot with six axes for maximum mobility

- Gripper adjustable to various bag weights and sizes

- Requires minimal programming and supervision

Economical

- Requires fewer modules than a conventional packaging line, reducing maintenance and acquisition costs

- No additional conveyors or standalone sealer are needed when combined with the 725 NXT Cleanpak

Compact and modular

- Typical cells fit in a 16' x 16' area (5 m x 5 m)

- Modules can be positioned according to the available room in your layout to maximize your floor space utilization

Options

- Robotic slip, top or tier sheet handling

- Automatic rejection of non-compliant bags by the robot

- Automatic bag size changeovers

- Stainless steel and food grade standards construction

- Safety upgrade for explosive products

- Additional interlocked gate for safety fences

- Integration with your current equipment

- Integrated metal detector installed on the packer

- Robotic programming to bring the bags to a sealer (if not integrated), printer, or Print and Apply labeling system

Specifications

Typical footprint: 197" L x 197" W x 98" H (5000 x 5000 x 2500 mm)

Bag dimensions: from 15 to 24" W (381 to 610 mm) x 15 to 34" L (381 to 864 mm)

Full pallet load (including the pallet): 48" L x 40" W x 71 " H (1219 x 1016 x 1800 mm)

Electrical requirements: 230/380/460/575 V 3ph, 50/60hz (different options available)

Get pricing and additional information

Need help finding the right valve bag handling equipment?

Request a quote

Tell us about your project, and we will reply with solution recommendations