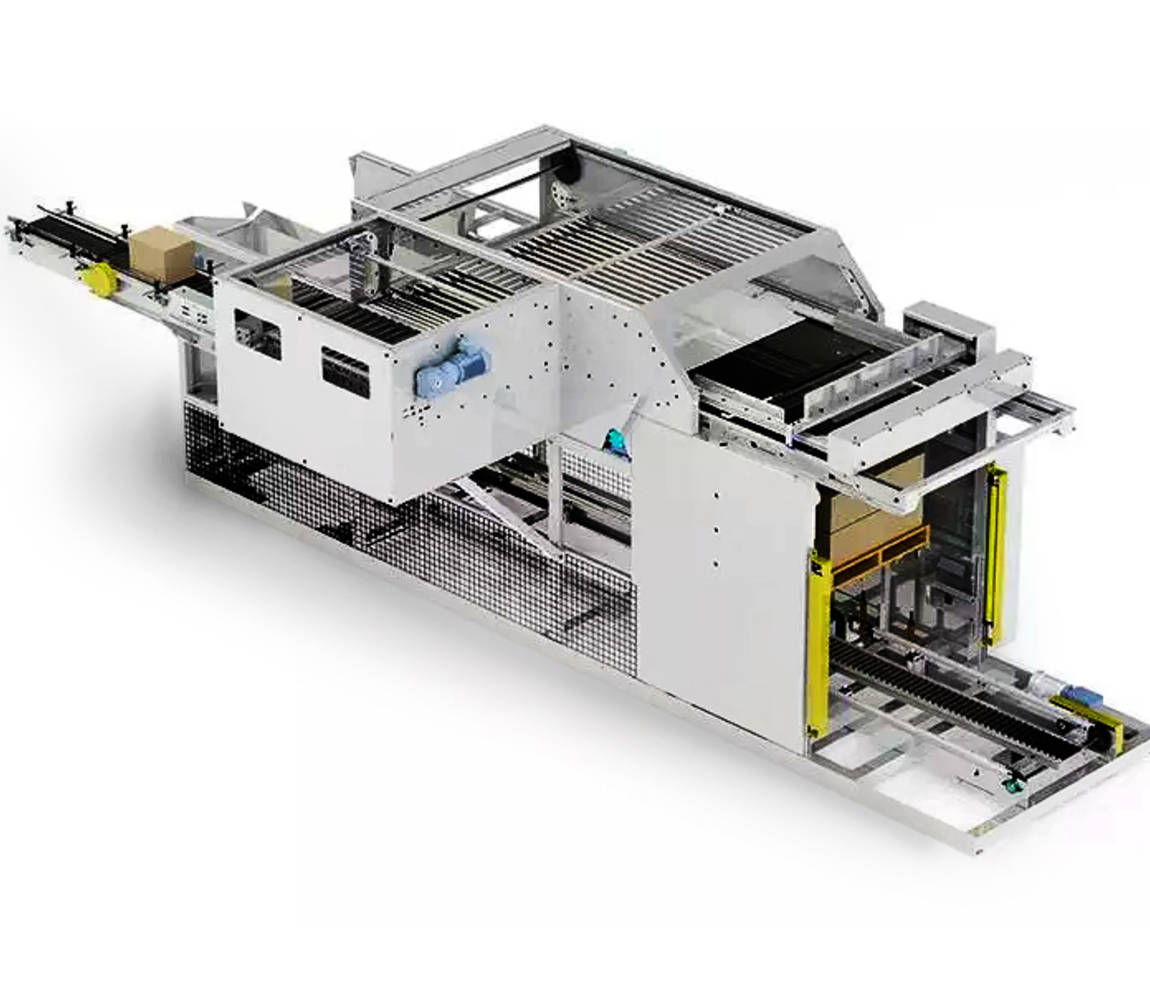

CHRONOS APH-5480High-speed palletizing machine

Available in

Canada & USA and Latin AmericaThe palletizer APH-5480 is engineered for manufacturers looking to optimize throughputs or upgrade existing equipment to provide a safer working environment. The palletizing solution brings speed, efficiency, and longevity while remaining price competitive.

It uses rugged construction, proven technologies, and several safety features to stack optimal and stable loads of many packages.

Speed: up to 75 units per minute

Applications: cases, boxes, crates, pails, totes, and bundles

Performant and long-lasting case palletizer

The APH-5480, formerly VG2200, builds on vonGAL’s experience to answer today’s most demanding palletizing requirement.

Designed to maximize throughput and uptime, it uses advanced technologies to palletize faster, reduce noise, and simplify maintenance.

The robustness of the components offers durability, especially when handling heavy products and layers. With suggested maintenance, the APH-5480 has been proven to last for decades.

- Rugged steel construction

- VFD control of motors for accurate, smooth, and refined motions

- Swift and precise turner with assist to help rotate longer and heavier cases

- Continuous overhead row pusher with surface plates to handle product gently and increase throughputs

- Quiet, electric hoist with a weight capacity of 4,000 lbs to handle the most common applications

Flexible palletizing equipment

The equipment easily adapts to your end-of-line packaging needs:

- Packages: Very flexible regardless of size variations. The standard machine handles products as small as 6" square and may be designed to go smaller.

- Pallets: Can work with multiple types and sizes.

- Patterns: Can create many simple and complex patterns, building a more robust or stable unit load for shipping

- Dispenser with a capacity of 10 to 12 pallets.

Practical palletizing software and safety features

The operator interface uses 3D images for easy comprehension. It provides a single location to check status, detect a fault, or view alarms.

The pattern software is intuitive and user-friendly. Operators may create new patterns easily or change SKUs automatically.

The palletizer system also provides comprehensive safety features compliant with Category 3, Performance Level D standards to help keep employees safe.

- Light curtains at full load discharge

- Handrails, fences, and interlocking trapped key

- Automatic lock on the hoist

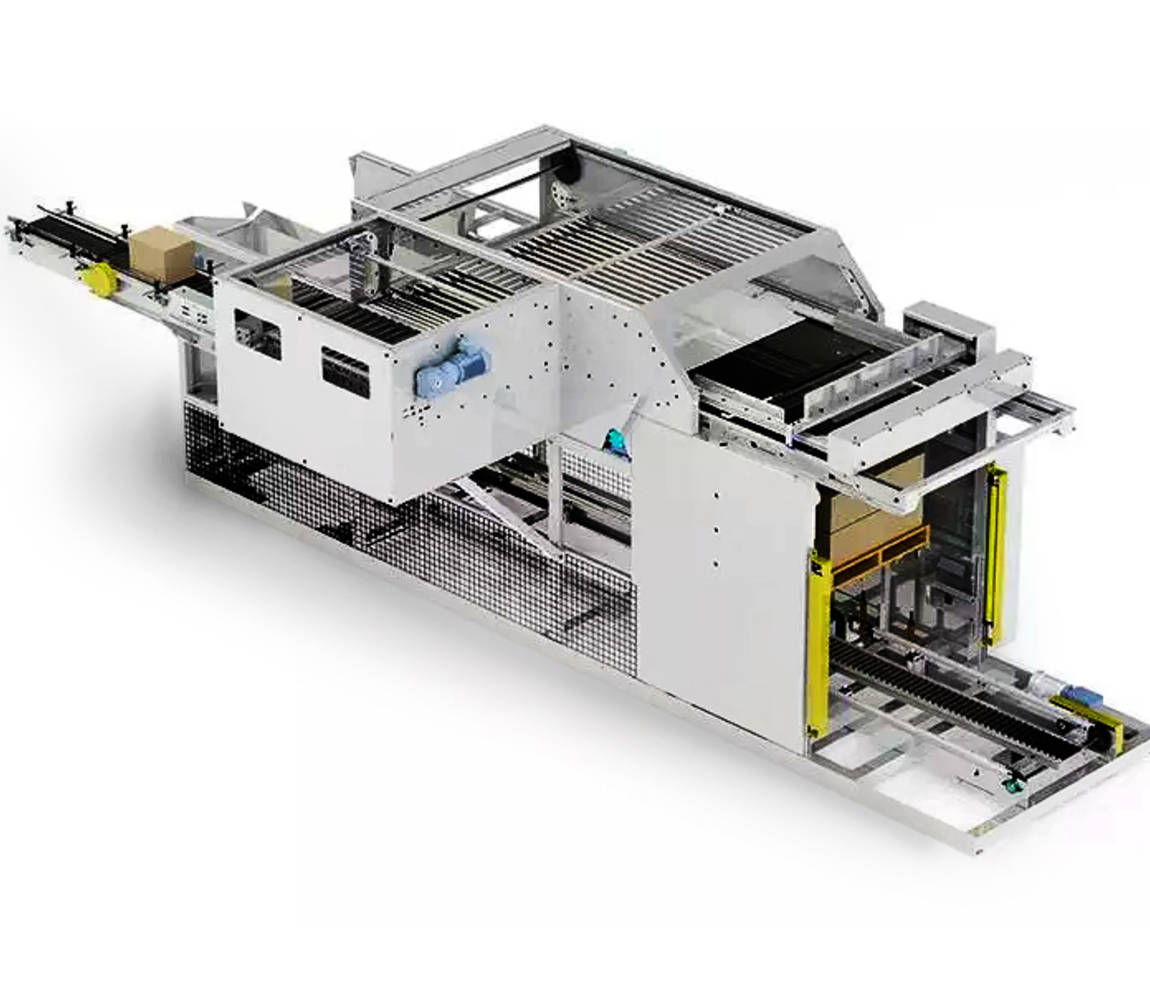

- The operator chooses a SKU or programmed pattern on the HMI.

- The pallet is lowered by the dispenser and conveyed to the hoist. A sheet can be applied if required.

- Products enter the top of the machine via a high-level infeed conveyor. The metering belt places a space between every unit. The turning device rotates the product into the correct position before moving to the row forming area.

- When a row is complete, the overhead row pusher gently sweeps it onto the area where the layer will be formed.

- This movement is repeated until the layer is completed. Then, a second overhead rake transfers it to the slide plates, providing faster rates and preventing stopping the product flow.

- The heavy-duty hoist raises the pallet while compression bars center the layer for more stability. The bi-parting slide plates open, depositing the products gently on the pallet or the previous layer.

- The hoist is then lowered, and the plates close. The layer-forming process is repeated until the pallet has the desired number of layers.

- The completed load is lowered and conveyed out of the machine, ready to be transferred or wrapped.

Additional options

The APH-5480 can be equipped with various options to fit your palletizing requirements.

- Sheet dispensers are available to help stabilize loads

- Polar Package using unique design and components rated for-20 ºF environment

- Wash-down parts for easy cleaning

- Expanded pallet dispenser capacity up to 25 pallets or multiple dispensers

- Elevating piers available to match existing infeed or discharge

- Ability to create taller loads to maximize the shipment truck space

Get pricing and additional information

Partnering in your success

Premier Tech offers unbeatable services and support throughout the lifecycle of your equipment.

Experts in packaging since 1989

Experts in packaging since 1989

Effective engineering capabilities

Effective engineering capabilities

Need help finding the right palletizer?

Request a quote

Tell us about your project, and we will reply with solution recommendations