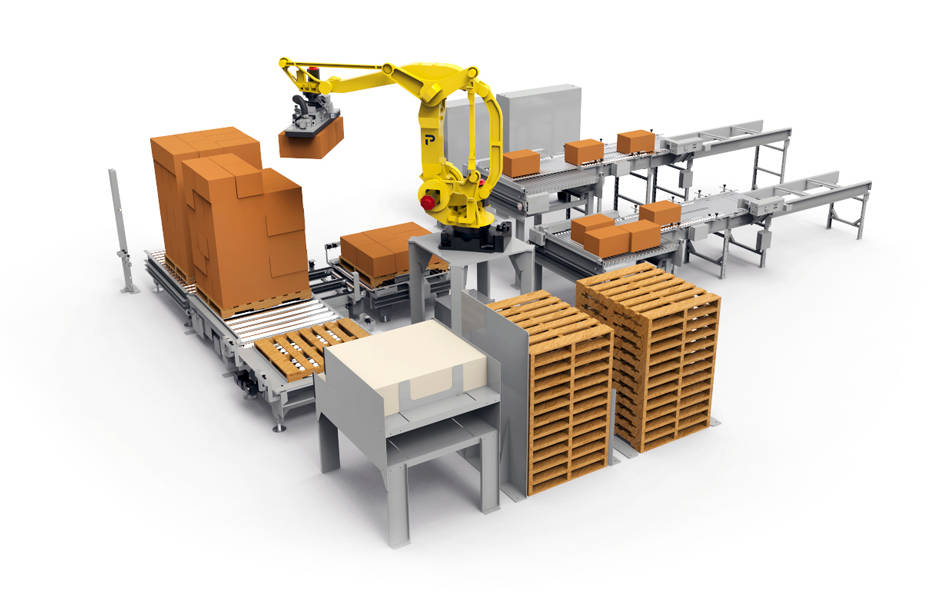

CHRONOS RPL-2000 SERIESFully automatic palletizing robot

Available in

Canada & USA and Latin AmericaThe RPL-2000 Series is ideal for facilities with moderate production rates that want to reduce manual operations, implement advanced equipment, and meet growing production demands.

The design leverages the robot’s agility and versatility to efficiently place pallets, slip sheets and units in the stacking position. This also eliminates the need for additional equipment and maximizes the use of floor space.

When completed, the load exits the cell automatically through a conveyor, significantly reducing the operator’s time spent in the cell.

Speed for cases: from 14 to 80* per minute (840 to 4800* per hour)

Speed for bags: up to 14 per minute (840 per hour)

Applications: bags, bales, bundles, cases, trays, and totes

*With multi-unit picks

Features

Reliable

- Robotic handling of pallets, sheets, and units

- Vast gripper selection to handle any type of unit with high accuracy

- Reliable and performant FANUC robot

Efficient

- Can be built with 1 infeed with 1 outfeed or 2 infeeds with 2 outfeeds

- Palletizing conveyor, pallet positioning device, alignment conveyor, and pick-up conveyor included

- Quick installation and commissioning

Safe and easy operations

- Built using low-maintenance and easy-to-clean components

- Safety fences, interlock doors, light curtains, and approved safety management software included

- Multilanguage HMI equipped with an integrated pallet configurator software

- Changeovers only take seconds thanks to stored recipes

Options

- Finger, clamp, or vacuum end effector

- Robot can be selected according to your application needs, such as speed, reach, and payload to optimize your cycle rates and costs

- Multiple infeed configurations to meet your desired production rate

- Sheet magazines and handling devices for increased autonomy

- Stainless-steel components to meet sanitary requirements and facilitate cleaning

- Integration with third-party printers, labelers, pallet and product traceability, and more

- Integration with pallet wrappers and conveyors

Additional options for bags

- Rejection conveyor for non-compliant bags

- Automatic bag width adjustment

- Weight check system

RPL-2111

- Up to 14 units per minute (840 per hour)

- Picks a single unit from 1 production line

- Places it on 1 stacking station on the motorized conveyor

RPL-2111

- Up to 14 units per minute (840 per hour)

- Picks a single unit from 1 production line

- Places it on 1 stacking station on the motorized conveyor

RPL-2311*

- From 30 to 80 cases per minute (1800 to 4800 per hour)

- Picks multiple units from 1 production line simultaneously

- Places them on 1 stacking station on the motorized conveyor

- Includes a preparation conveyor where the units are gathered

- Achieves higher production rates

*For cases only

RPL-2311*

- From 30 to 80 cases per minute (1800 to 4800 per hour)

- Picks multiple units from 1 production line simultaneously

- Places them on 1 stacking station on the motorized conveyor

- Includes a preparation conveyor where the units are gathered

- Achieves higher production rates

*For cases only

RPL-2322*

- From 30 to 80 cases per minute (1800 to 4800 per hour)

- Picks multiple units from 2 production lines simultaneously

- Places them on 2 stacking stations on the motorized conveyors

- Includes 2 preparation conveyors where the units are gathered

- Achieves higher production rates

*For cases only

RPL-2322*

- From 30 to 80 cases per minute (1800 to 4800 per hour)

- Picks multiple units from 2 production lines simultaneously

- Places them on 2 stacking stations on the motorized conveyors

- Includes 2 preparation conveyors where the units are gathered

- Achieves higher production rates

*For cases only

Get pricing and additional information

Need help finding the right palletizer?

Request a quote

Tell us about your project, and we will reply with solution recommendations