CHRONOS APH-5300Compact palletizing machine

Available in

Canada & USA, Latin America and OceaniaThe APH-5300, formerly known as the vonGAL SPLXC, is one of the most compact palletizers in the industry. It is engineered to take up minimal surface area, making it the preferred choice in facilities where floor space is at a premium.

With speeds reaching up to 45 units per minute, it stacks various types of containers with consistent, accurate, and repeatable results.

Speed: up to 45 units per minute

Applications: cases, boxes, crates, pails, totes, and bundles

Great functionalities in a compact design

The APH-5300 uses the same proven technologies as our larger palletizing solutions, such as the APH-5360 (formerly the SPLX MKII). However, it is three feet shorter and eight inches narrower. It includes:

- Strong, sturdy, and low-maintenance components.

- Variable frequency drives (VFD) to perform smooth and controlled movements. This technology handles products gently, while reducing the equipment's overall noise level.

- A pallet dispenser that positions pallets automatically onto the hoist to limit human intervention.

A sheet dispenser and an optional integrated stretch wrapper may be added to optimize load security.

Simple and efficient human-machine interface

The palletizer's software interface uses visual elements to simplify operations. It also comes with multiple password-protected user levels to minimize entry errors.

The HMI provides manufacturers with total control over pattern and product changeovers as well as the ability to upgrade as their businesses grow.

- Intuitive and user-friendly PLC and HMI

- Quick changeover of palletizing patterns via stored recipes

Increased productivity and safety

The automatic palletizer performs repetitive and heavy motions to improve outputs while helping reduce employee injuries.

It comes with safety light curtains, handrails, interlock doors, and automatic safety latches on the elevator to ensure the workers’ safety.

- Compliant with Performance Level D and Category 3 safety standards

- The operator chooses a pre-programmed pattern on the HMI.

- A pallet is dispensed to its stacking position on the hoist. A sheet can be applied if required.

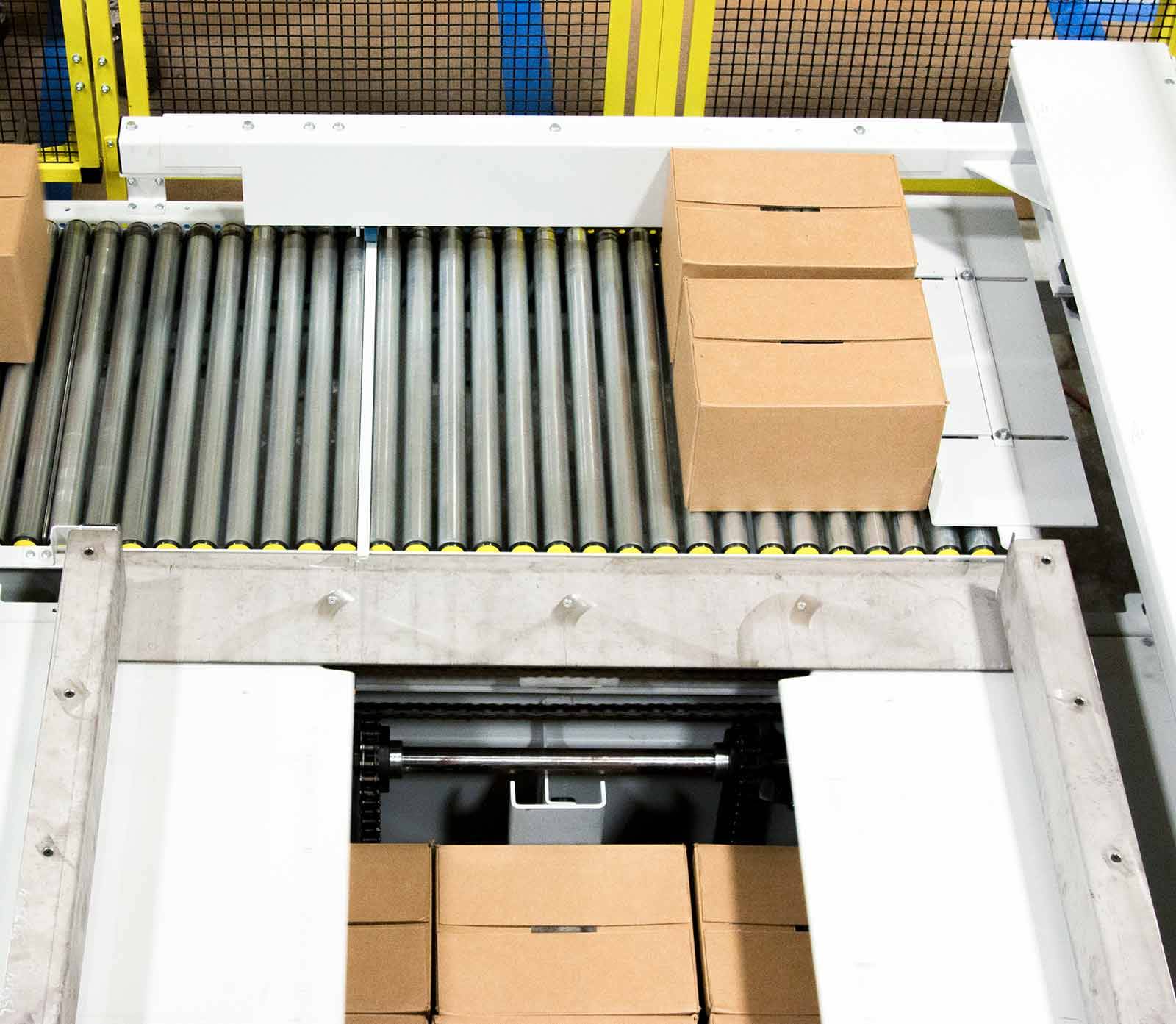

- Cases are brought into the machine from a high-level case conveyor and metering belt. They are oriented and positioned in a row according to the pattern.

- When a row is formed, it is swept onto the slide plates. This process is repeated until an entire layer is formed.

- When completed, lateral bars gently compress the layer to the center to increase stability and minimize damage during shipment. While the layer is being compressed, the heavy-duty elevator raises the pallet, and the bi-parting slide plates open, depositing the products gently on top.

- The hoist is lowered, and the process is repeated until the pallet load is completed.

- Once done, the entire pallet is lowered to the discharge conveyor, and a new pallet is retrieved from the dispenser.

Additional options

The APH-5300 can be equipped with various options to fit your specific palletizing requirements.

- Sheet dispenser to stabilize loads

- Polar Package using unique design and components rated for -20 ºF environment

- Wash-down parts for easy cleaning

- Integrated pallet wrapper to secure loads

- Lift-up rake to optimize speed

Get pricing and additional information

Partnering in your success

Premier Tech offers unbeatable services and support throughout the lifecycle of your equipment.

Experts in packaging since 1989

Experts in packaging since 1989

Effective engineering capabilities

Effective engineering capabilities

Need help finding the right palletizer?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations