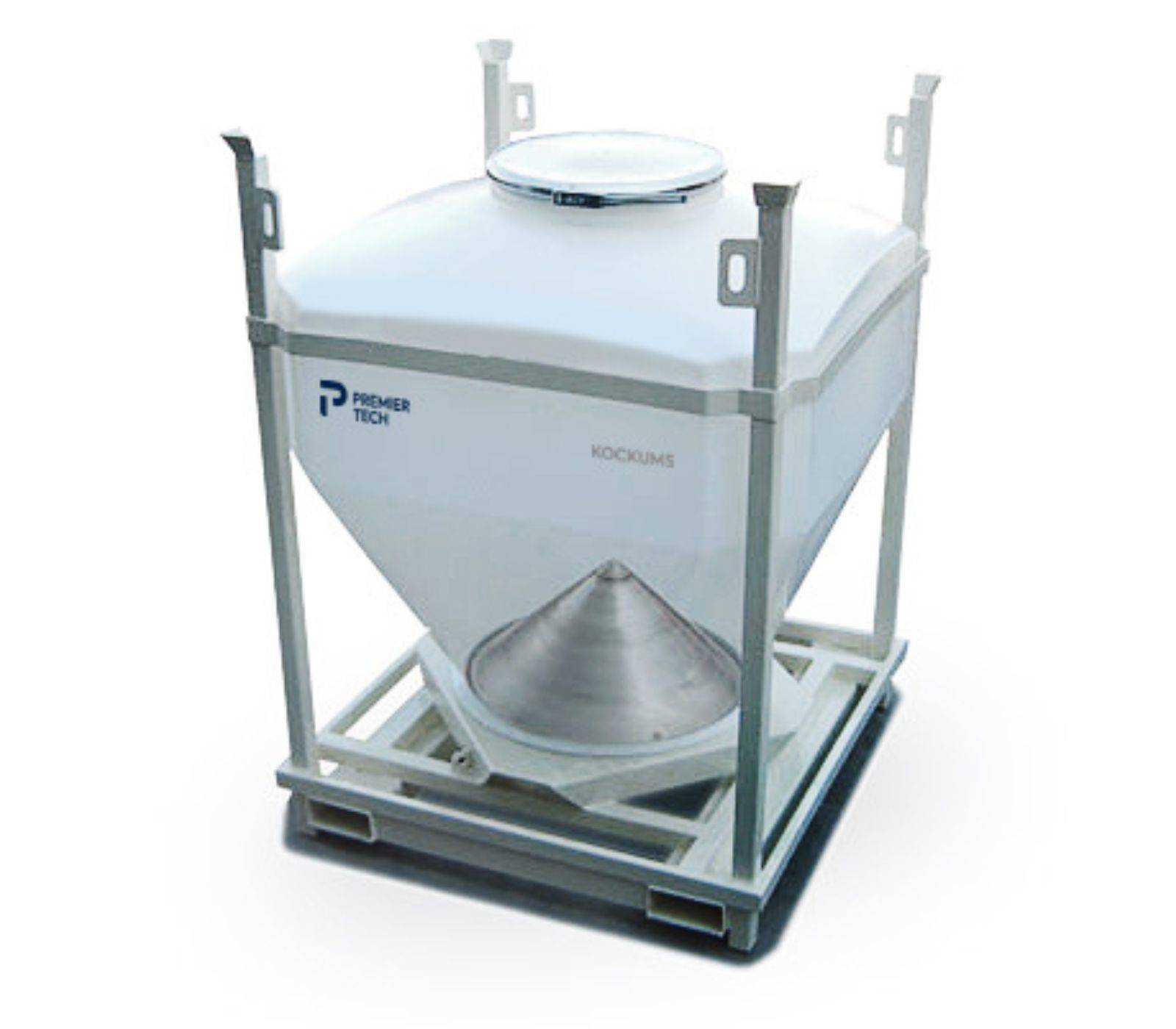

KOCKUMS

Cone valve for integrated bulk containers

Available in

Asia, Canada & USA, Latin America and OceaniaCone valve technology can be used to facilitate material flow in mobile intermediate bulk containers (IBCs) or stationary hoppers.

The cone can be raised, lowered, pulsed, or vibrated to control the material discharge, and the process can be fully automated. This complete automation eliminates the need for operators to access high levels above the equipment to open the IBC outlet, unlike bulk bags or other IBCs.

Once a batch is complete and the cone valve is closed, the IBC with its partial content is sealed and easily removed and placed back into storage.

Bulk materials:flakes, granules, pellets and powders

Features

Sanitary

Hygienic design for quick easy cleaning.

Performance

IBC’s offer the ability to contain and easily trace recipes throughout the plant aiding production quality control.

Design Quality

The system is simple, easy to keep clean, reliable, and effective in operation.

Specifications

The CONE VALVE is designed to promote material flow, without segregation.

Hygienic design aides easy offline cleaning without downtime.

Capable of metering directly into the process, manually or automatically.

Ability to grow the system within your production process.

Stackable for space saving storage.

Full containment once the CONE VALVE is closed.