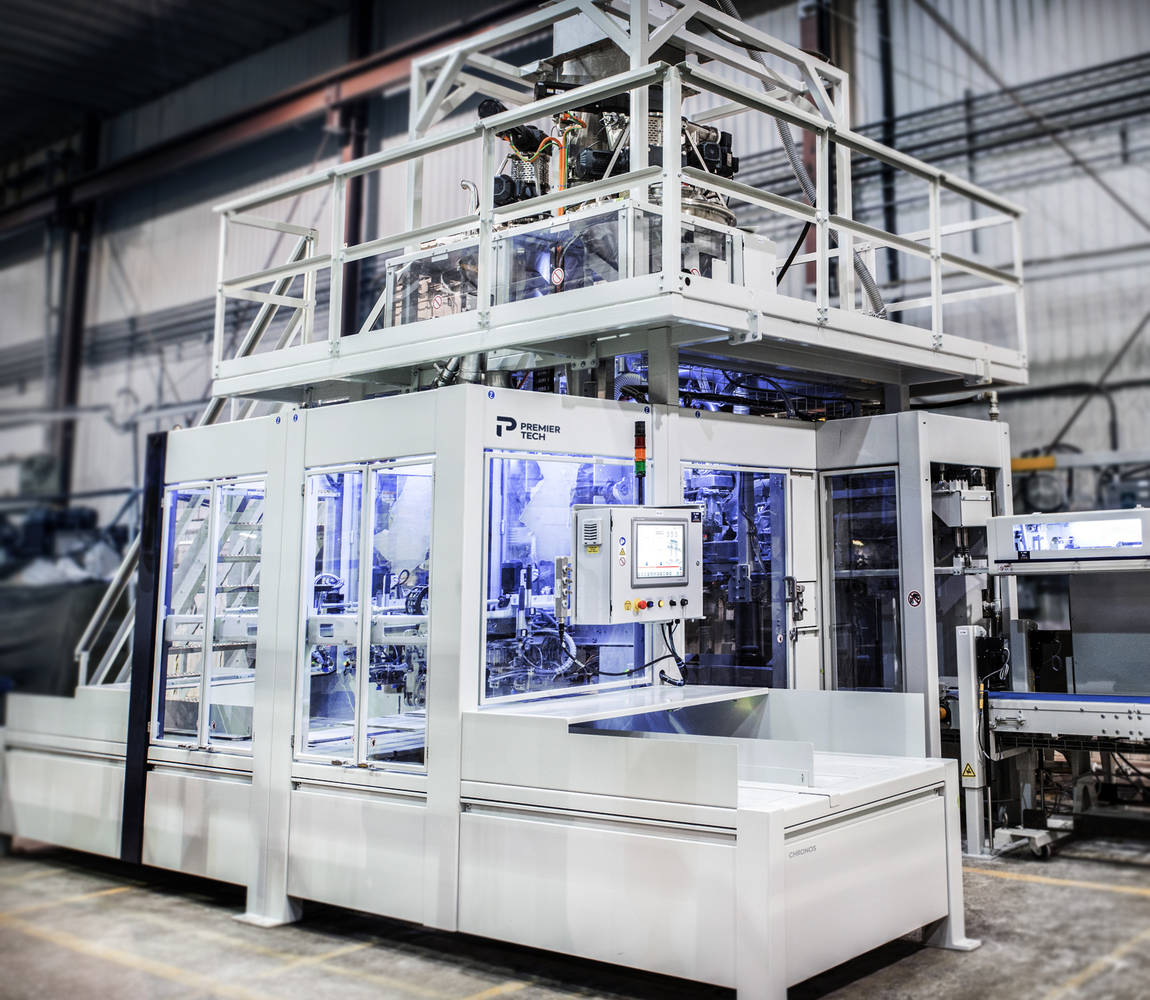

CHRONOS BFL SERIESHigh-precision open-mouth bagger for powders

Available in

Africa, Asia, Canada & USA, Europe, Latin America and OceaniaThe BFL Series is an automatic open-mouth bagging equipment designed for quick and precise dosing of powders.

The patented powder bagging machine fills bags from bottom to top, reducing dust emission and keeping product aeration to a minimum, which is ideal when packing flour or other powdery products. The filling is done in two distinct steps, coarse and top-up fine filling, to reach target weights quickly and accurately.

The innovative dust-free bagging process is highly safe for operators. It is simple and intuitive to use and requires little maintenance. It offers a short payback period and 3X less product giveaway than any other technology on the market.

Speed: up to 20 bags per minute (1200 per hour)

Bulk materials: powders and fine powders

Bag types: gusseted, gusseted flat bottom, and pillow

Bag materials: paper, PE, and woven PP

Bag weight: 22 to 110 lb (10 to 50 kg)

Features

Accurate

- The powder bagging machine combines a gross weigh scale for precise dosing (up to 25 grams @ 2 sigma)

- No filling fluctuations

- Limits the amount of air that enters the bag

Highly performant

- 98% uptime at maximum output rates

- Servo motors control the equipment’s main components, allowing for speed, repeatability, and reliability

- Quick bag changeovers with automatic adjustments to adapt to many bag sizes

Hygienic and safe

- Centralized dust collection ducting for greater cleanliness and easy installation

- Enclosed environment to reduce foreign object contamination and human contact

- Parts in direct contact with the product are made of stainless steel

- Main frame structure is made of welded structural steel

- Access doors fitted with safety switches

- Ergonomic bag magazine

- Designed under NFPA standards to control explosion hazards (ATEX and IECEX versions available)

Options

- Customized in-feed system

- Vacuum lance

- Bag top de-aeration and alignment for consistent seals

- Compatible with our pinch-top bag closing equipment

- Pinch bags top flap folding

- Filled bag turners (kicker, inline, etc.)

- Printing and tagging integration

- Flattening press and metal detector

- Food-grade construction

- Upgrade available to 3-A sanitary standards

- Clean-in-place (CIP) system

- C2D2 Certification by Intertek for safe use in explosive environments across various projects

Specifications

Typical footprint: from 159"–229" L x 142" W x 228"–234" H (4040–5815 x 3605 x 5790–5945 mm)1

Bag dimensions: from 12–22" W (300–560 mm) x 23–40" L (580–1000 mm)

Bag magazine capacity: up to 500 bags2

Electrical requirement: 460 V / 3Ph / 60 Hz, 120 V / 1 Ph / 60 Hz

Operating temperature: 40 °F to 95 °F / 5 °C to 35 °C

1 Depending on the model

2 Depending on the model, bag thickness, and number of bag piles

BFL-2120

(Previously PTF-1200)

- Up to 20 bags per minute (1200 per hour)

- 2 filling spouts

- 2 bag magazines

- Allows for bagging two different products simultaneously while avoiding cross-contamination

BFL-2120

(Previously PTF-1200)

- Up to 20 bags per minute (1200 per hour)

- 2 filling spouts

- 2 bag magazines

- Allows for bagging two different products simultaneously while avoiding cross-contamination

BFL-1060

(Previously PTF-1060)

- Up to 10 bags per minute (600 per hour)

- 1 filling spout

- 1 bag magazine

- Ideal for chemical products

BFL-1060

(Previously PTF-1060)

- Up to 10 bags per minute (600 per hour)

- 1 filling spout

- 1 bag magazine

- Ideal for chemical products

Get pricing and additional information

Need help finding the right open-mouth bagger?

Request a quote

Tell us about your project, and we will reply with solution recommendations