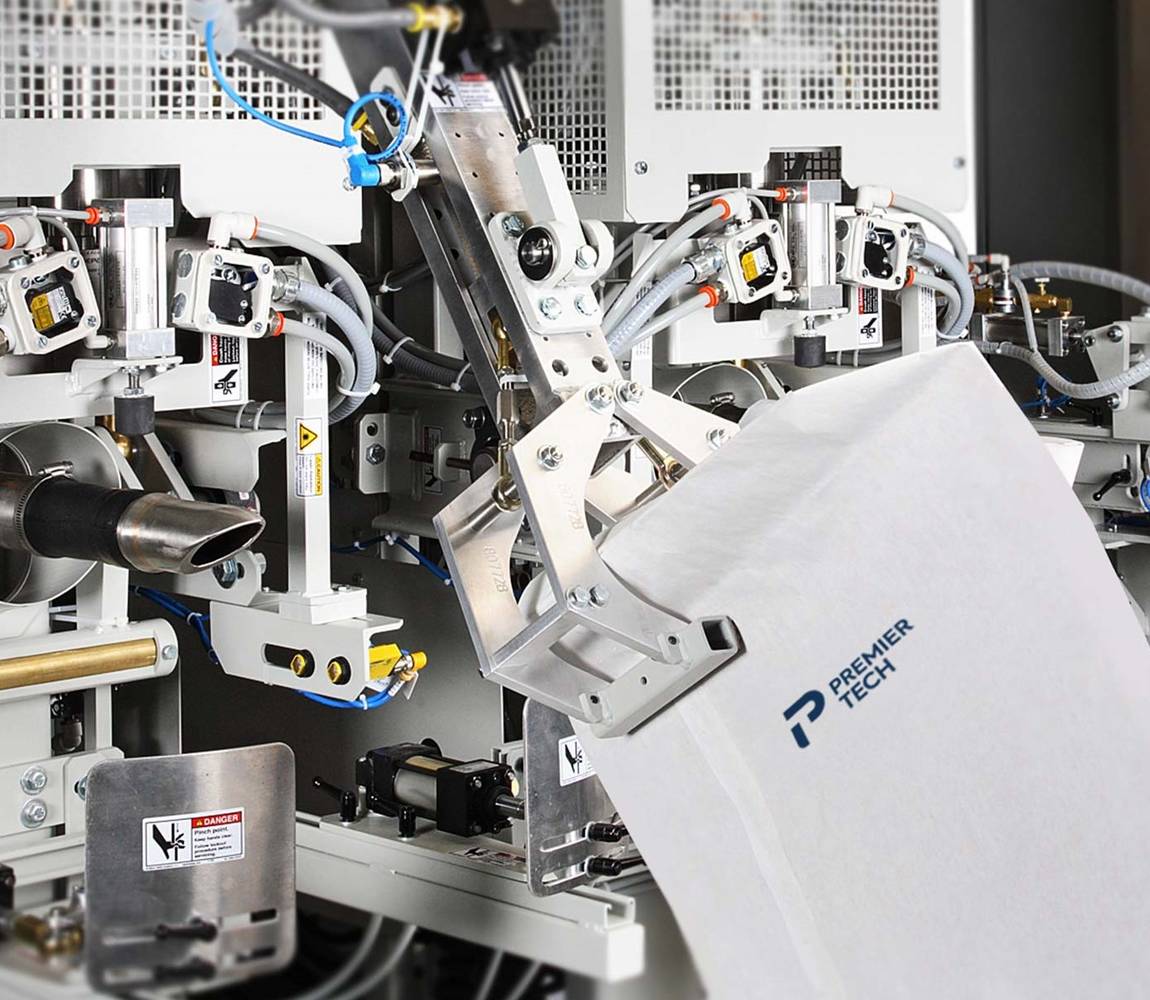

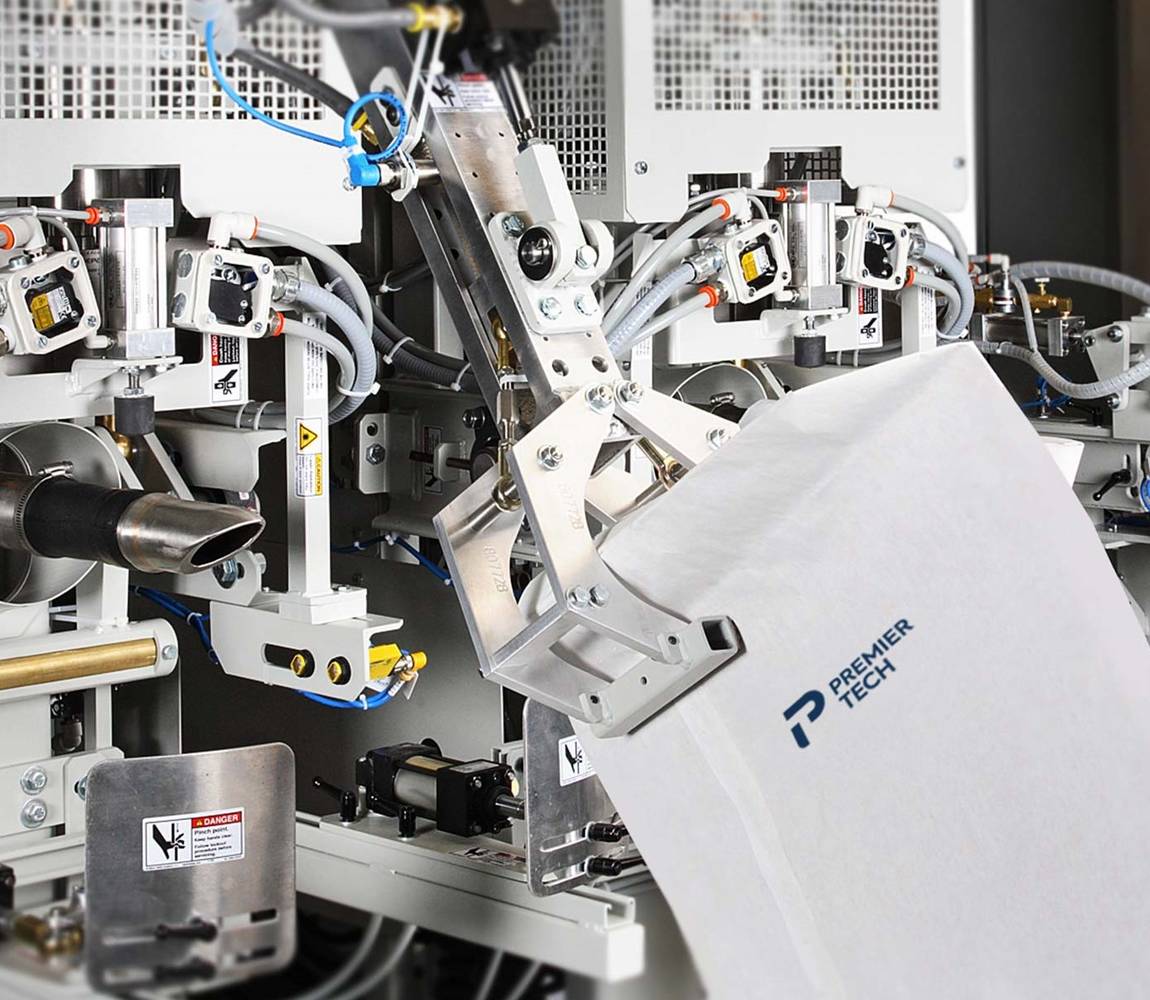

CHRONOS VPF SERIESForce Flow Air Packer

Available in

Africa, Asia, Canada & USA, Latin America and OceaniaThe Force Flow Air Packer (former 725 Series) offers excellent weight accuracy and simple operation. The filling and weighing system is fully integrated into a single machine and under a single interface.

This pneumatic packer uses air to bag products, providing faster filling. A versatile packing solution, this machine can handle fine powders, flakes, pellets, and granules with a particle size of 3/8'' or smaller, such as chemicals, minerals, and food products.

Multiple units may be banked together under a single hopper to provide higher production rates. A version with an integrated sealer mounted to the packer’s frame is also available, ensuring clean operations and improved bagging accuracy.

Speed: up to 10 bags per minute (per spout)

Bulk materials: fine powders, flakes, granules, pellets

Bag types: valve

Bag materials: paper

Bag weight: 22 to 110 lb (10 to 50 kg)

Features

Accurate

- Excellent weight accuracy (2 ounces at two sigma for many products)

- Bulk and dribble product flow for a slow “top-off” that improves accuracy (electronic models only)

- Inflatable sealer closes off the gap between the filling tube and the bag’s valve to minimize dust during filling

Ease of use

- Easy changeover with a quick-drop bottom for clean-out between runs

- Low maintenance with no moving parts in the product’s path

Well-constructed

- Small footprint as multiple machines can be banked together under one bin

- Laser cut and bolted frame

- Minimal ledges to prevent product or dust build-up

- Plumbing and wiring is internally routed and protected by the sleek steel framework

- Designed to be used with the Middle Range NXT and MP family of Electronic Weight Controllers

- Stainless steel product contact parts

Options

- Atmospheric configuration for lowered machine cost

- Plug/stack configuration for handling granular or pellet products

- Potbelly-style chamber for low-head applications

- Built for use in II-G-1 and II-G-2 dust explosion environments

- Metal detector mounted around gum rubber filling tube behind fill spout

Get pricing and additional information

Need help finding the right valve bag filler?

Request a quote

Tell us about your project, and we will reply with solution recommendations