Retrofits for APH-5300 (former SPLX)

Your compact case palletizing machine can benefit from retrofits that reduce equipment maintenance, improve performance and are equipped with an overall better, evolved design.

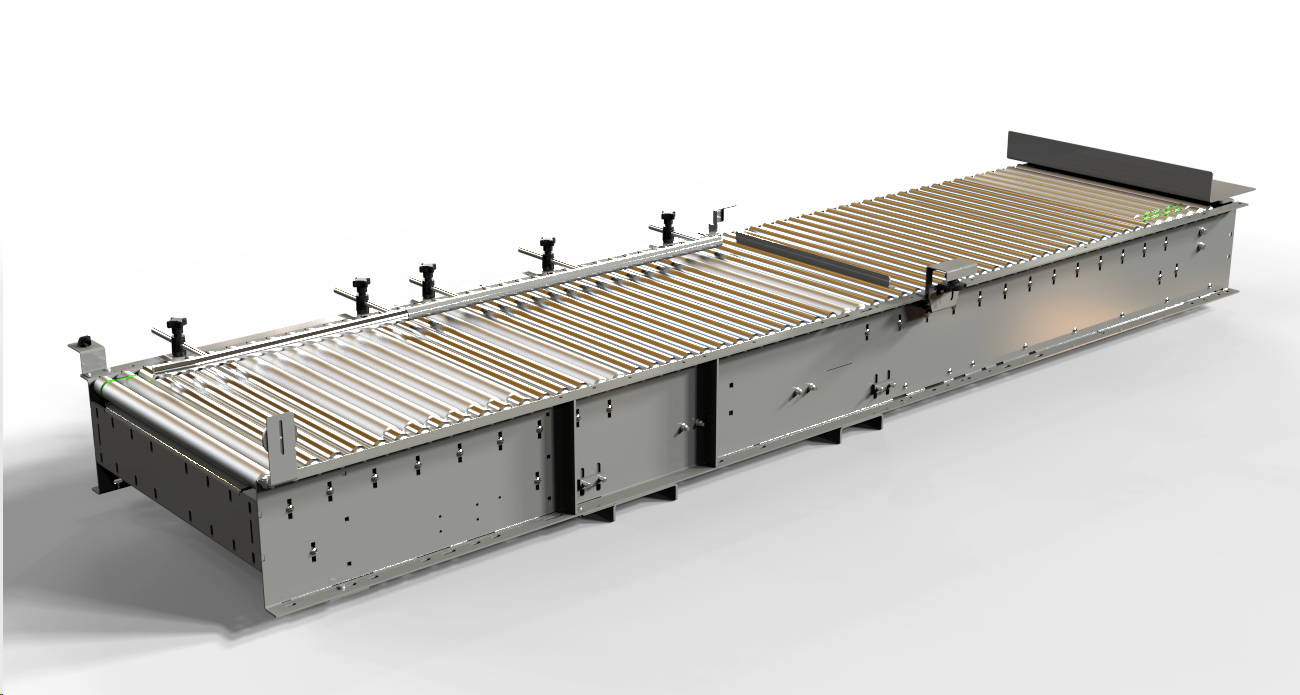

Belt driven infeed live roller

This retrofit upgrades equipment with a belt-driven live roller system, replacing the old chain-to-chain roller system.

Retrofit main benefits

- Less maintenance required

- Smoother and quieter operation

- Closer roller center spacer for improved product

Turner

This upgrade is a redesigned turner, offering a larger surface area for product contact while ensuring gentler handling and no product damage.

Retrofit main benefits

- Adjustable to meet your product turning needs

- Air cushioned turning

- Padded and larger surface area to contact your product

- Can be fitted with a turner assist for long cases over 12"

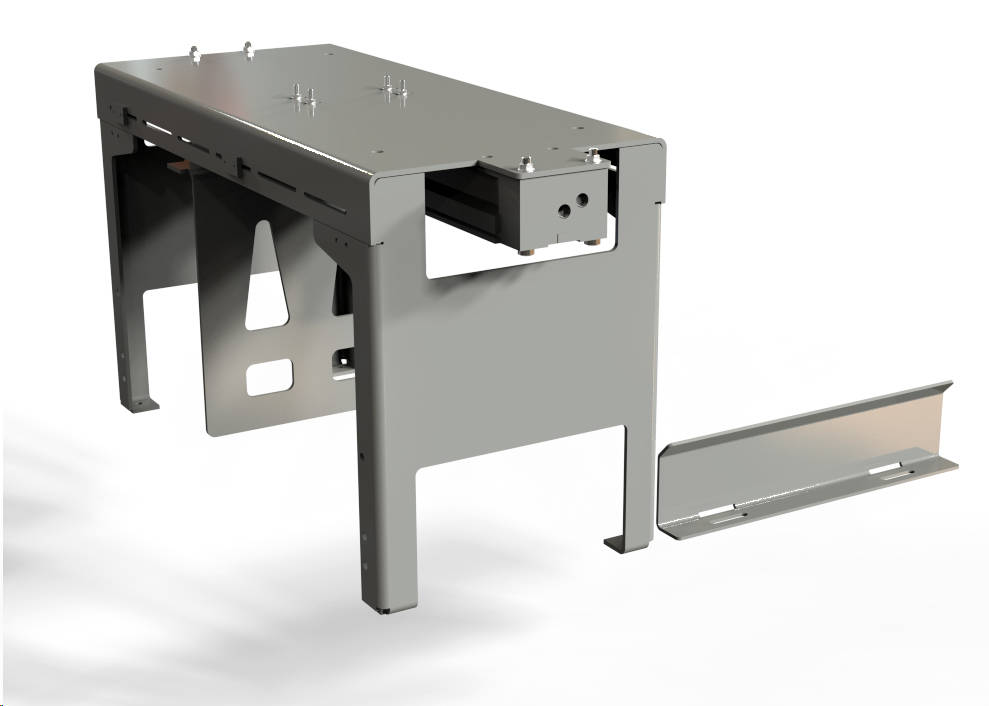

Pushover

This retrofit replaces the current side-mounted pushover with an overhead actuation system to enhance case stability during pushing. This retrofit is recommended for all live rollers but is standard for an upgraded belt-driven live roller.

Retrofit main benefits

- Adjustable for use as a half push

- Overhead actuation to assist with tall or top-heavy products

- Increased throughput for some products/patterns

Tie sheet dispenser

This upgrade allows the palletizer to place sheets either on empty pallets, between layers, or on top of a load when the same type of sheet is used for all positions. This retrofit is only available if the SPLX has been retrofitted prior with an MKII-style rake and side compression system.

Retrofit main benefits

- Better load building, stability, and securing

- Placing sheets on pallets at floor level or from top of palletizer

- Allowing better product protection on the pallet from floor or ground

Elevator VFD and motor

This retrofit replaces the double speed 7.5hp gearmotors, which are now obsolete, with the 10hp motor with variable frequency drive (VFD). It makes it easier and quicker to change pallets, contributing to an increase in overall throughput.

Retrofit main benefits

- Better gearmotor efficiency

- Quicker pallet changeover

- Better elevator positioning

- Better control and less vibration

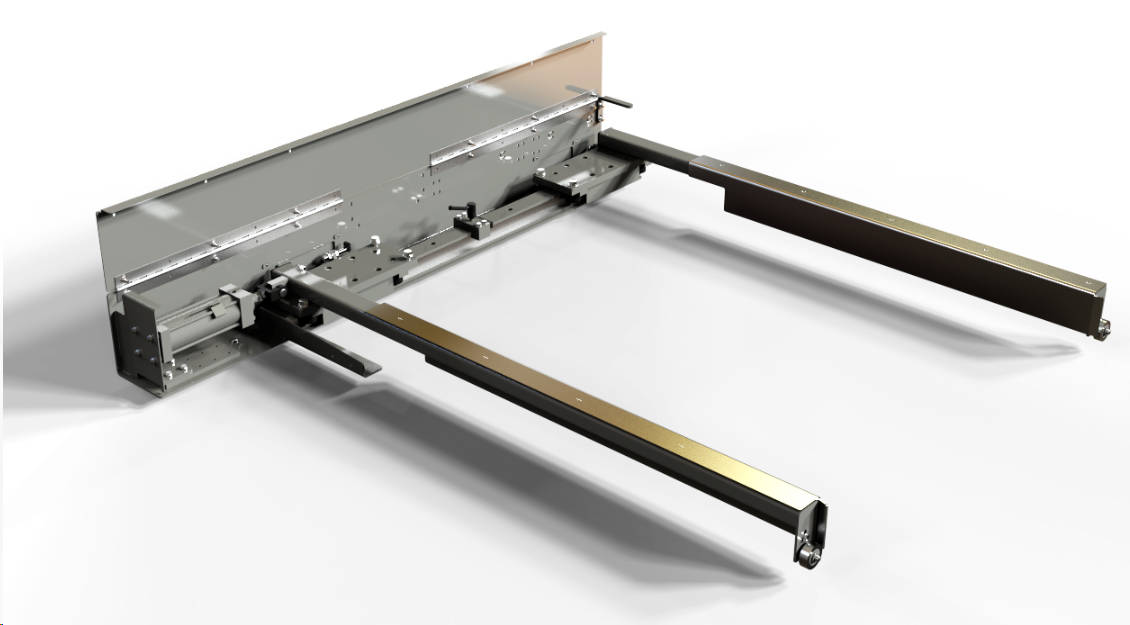

Lift up rake and side compression

The rake arm and support are raised above the tallest cases, and the faceplate of the rake arm actuates up and down. After raking a row or layer into place, the faceplate can be retracted up and over incoming cases, thereby increasing the number of cases processed per minute.

Retrofit main benefits

- Allows higher rake strokes per minute

- Up to 20% higher rates

Can't find what you're looking for?

We would love to hear from you! If you have any questions or want to know more about our Client Solutions Team, click on the button to reach us.